Since 1981, the United States military has been providing nourishing meals to its enlisted soldiers via Meal, Ready-to-Eat rations. These packaged meal alternatives help keep up endurance, strength, and motivation.

As any hard worker knows, hunger can be a highly detrimental distraction, leading to a loss of focus on the job. It’s important for the men and women defending our country to consume adequate nutritious goods that are easy to carry, open, and ingest during the stressful times in battle.

Until the ‘80s, the military used bulky cans or cardboard cartons for its combat rations. You can see why improvements have been made in terms of the food packaging — cans and boxes are heavy and don’t aren’t practical or conducive to soldiers’ lives during wartime. These brave fighters need healthy food packaged in lightweight containers that can be easily carried on their person and keep rations protected from outside contaminants and debris.

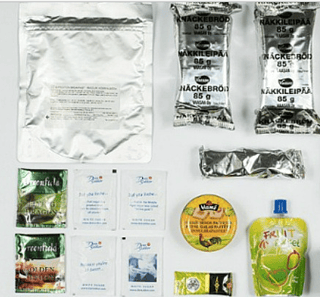

Scientists at the U.S. Army Natick Soldier Research, Development and Engineering Center are looking to further innovate the type of food packaging used for combat rations by switching away from foil bags. Non-foil materials are preferred because they have less of an impact on the environment and reduce weight and burden on the warfighter. Meal rations generate a lot of waste, and the eco-friendlier the food packaging, the better. The military made the wise decision to switch to flexible retail packaging for their soldiers’ chicken, rice, stew, noodles, and other nourishing meals that can be eaten on the go. Now, choosing food packaging made of structurally sound, environmentally friendly structural elements should remain a top priority.

In an effort to leave less of a negative impact on the earth, the military previously explored using paper for materials (like strapping for ration cases). Maintaining this same mindset can help point researchers in the right direction in terms of the packaging for replacement meals. There is a seemingly endless selection of options in the flexible retail packaging world — including kraft stand up pouches, which are made from environmentally friendly paper exteriors, laminated with multiple protective layers that keep food fresh and shelf stable.

Food Saver bags are another option used for vacuum-sealed food that is not exposed to oxygen or moisture, thus preserving the quality of the meals inside. No matter which flexible retail packaging option the military chooses, they can be sure today’s stand up pouches and bags are made from food-grade, FDA-approved materials that won’t harm consumers.

It’s so important to keep soldiers’ food safe and free from water, hot temperatures, chemicals, and bacteria as they live and fight in rugged and uncertain environments. Choosing strong, flexible retail packaging made of environmentally sound materials is key to ensuring the meals are protected and the packages aren’t littering and harming the earth. Stand up pouches and barrier bags help maintain the vitamin and nutritional content of food and can easily slip in a pocket or bag without putting an extra burden on soldiers.

We can learn important lessons from the military regarding the safety of our food and quality of life on our planet. If flexible retail packaging is the preferred option for our brave warfighters’ meals, it should also be the standard for all consumers around the country. It’s the best solution for keeping food fresh and protected from outside elements while producing less waste and enhancing the quality of the goods inside.

(Photo Sources: Boston.com, FoodBeast)