Introduction

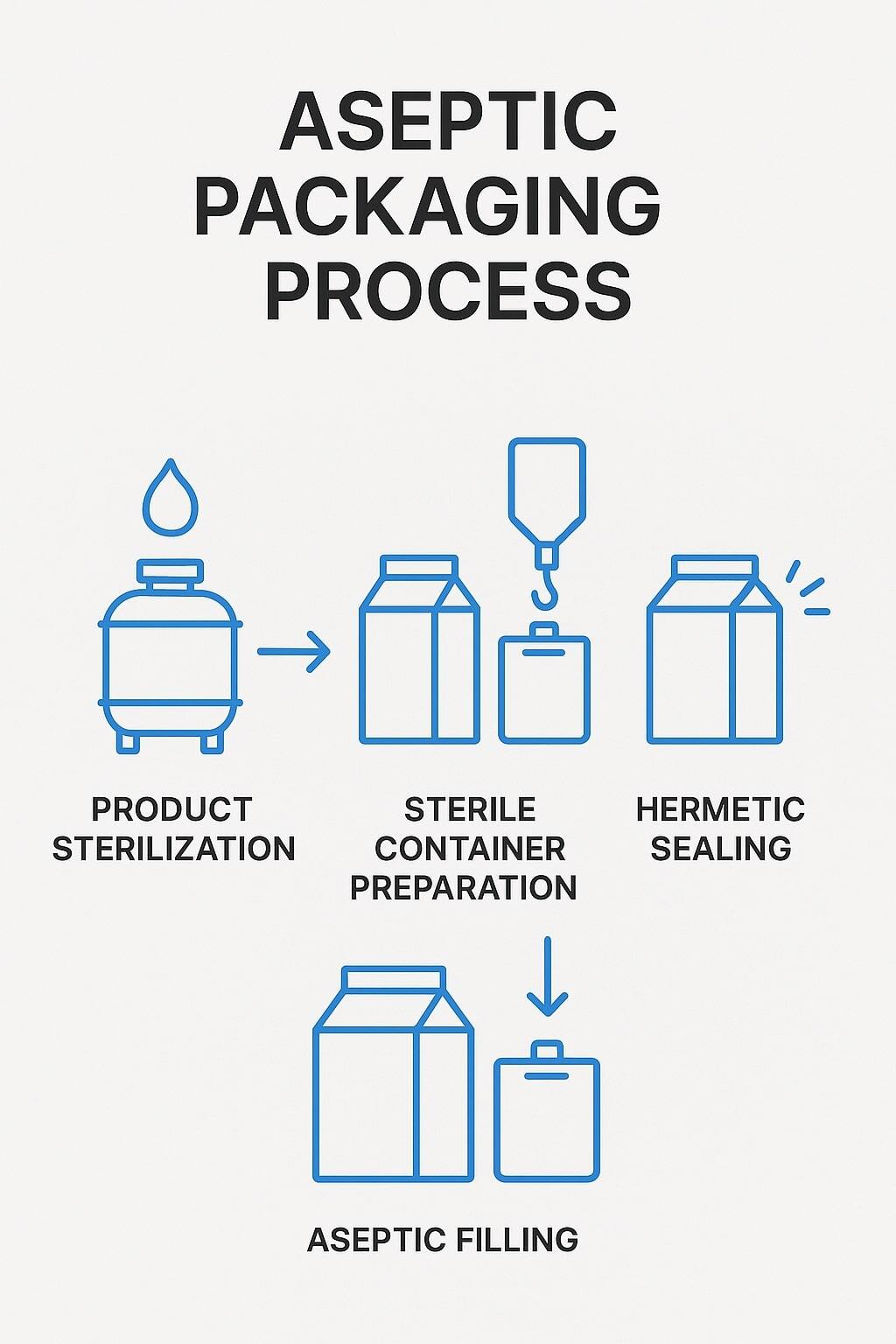

Aseptic packaging is one of the most advanced methods of food and beverage preservation. It combines sterilized products with sterilized containers in a controlled environment, ensuring long shelf life without refrigeration or preservatives. This guide explains how aseptic packaging works step by step, including its process, costs, risks, comparisons, real-world examples, and best uses.