Introduction

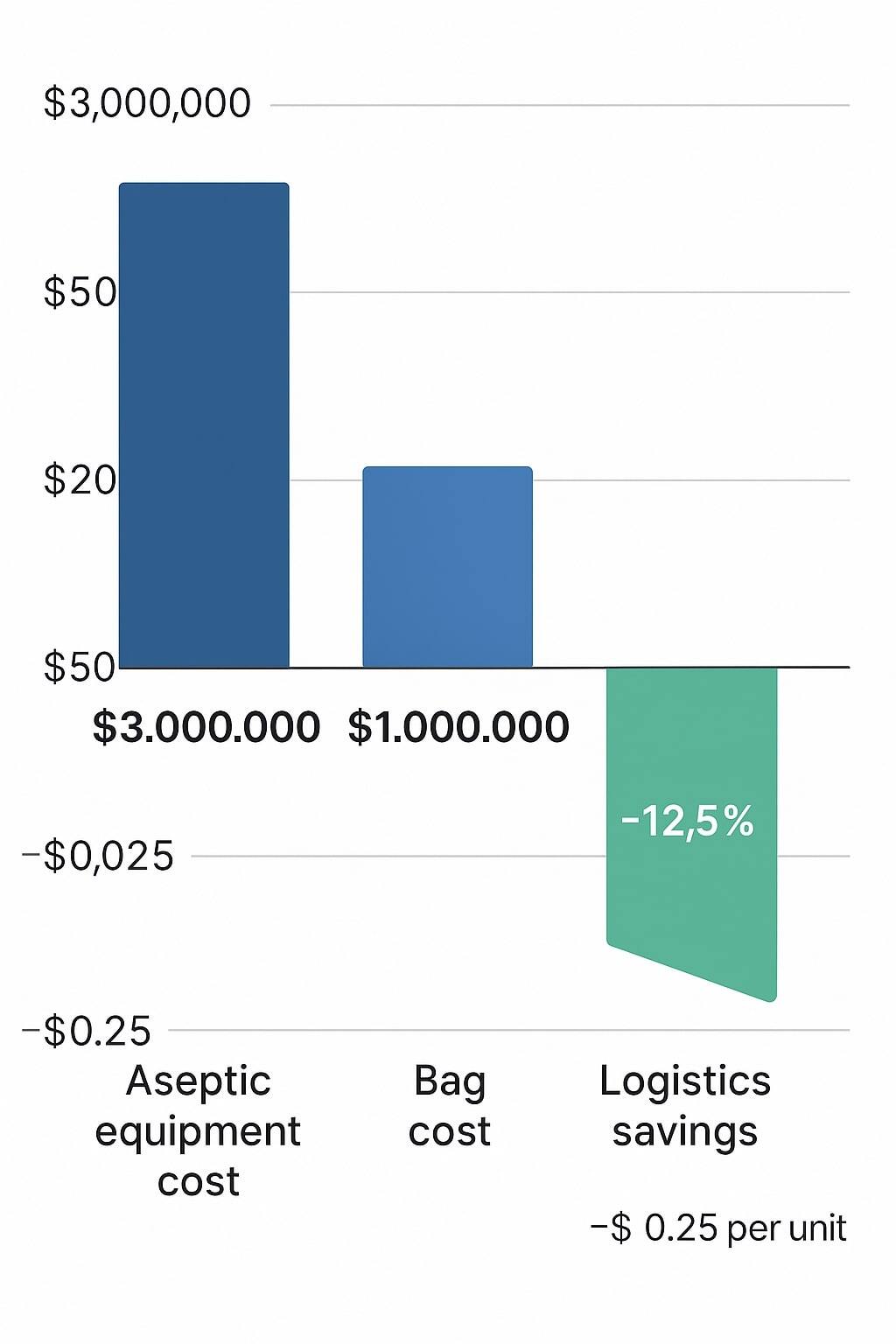

The cost of aseptic packaging can appear high at first glance, but when broken down into equipment, materials, and logistics, it often delivers long-term savings. Brands that invest in aseptic systems gain extended shelf life, reduced waste, and entry into new markets without refrigeration. For full context on the end-to-end process, review the step-by-step aseptic packaging guide.