How Aseptic Packaging Scales Shelf Life & Savings

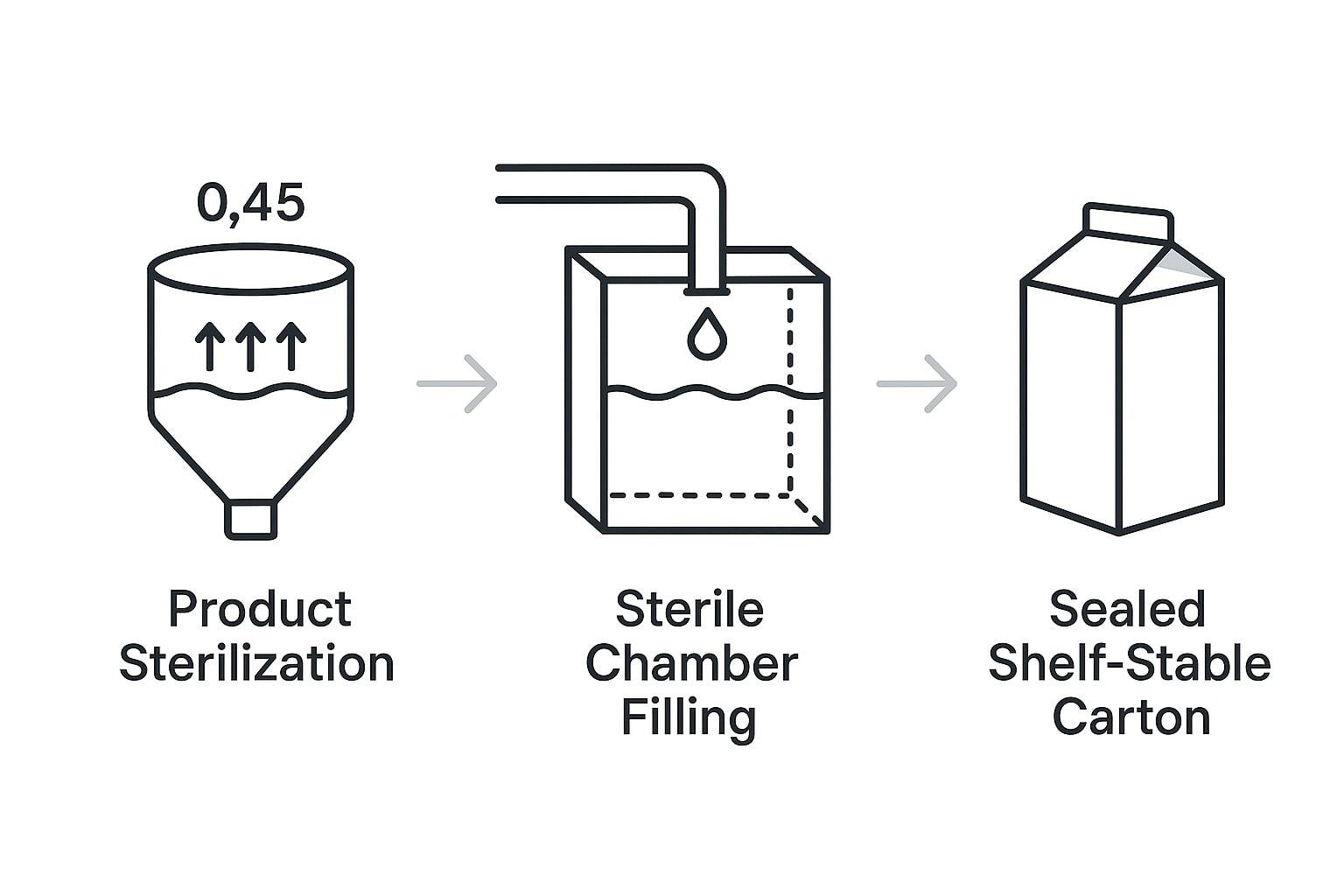

If you’re weighing packaging systems for beverages or ready-to-eat foods, aseptic technology deserves a close look. Our step-by-step guide to aseptic packaging breaks down sterilization, filling, and sealing in plain language, showing how the process reliably delivers 6–12 months of ambient shelf life. By removing cold-chain requirements, brands gain flexibility to ship farther, reduce energy costs, and minimize spoilage-related losses.

Cost perception is a common hurdle. Upfront equipment and specialized materials can be higher than traditional approaches—yet the true cost of aseptic packaging trends lower at scale as refrigeration and waste decline. For teams planning national or international expansion, aseptic often becomes the most economical path over the product lifecycle.

Risk & Readiness

Any high-performance system requires diligence. Our primer on aseptic packaging risks covers investment, compliance, and operator training—plus how to mitigate them with proven SOPs and maintenance plans. If you’re comparing formats, don’t miss our overview of aseptic vs. traditional packaging across shelf life, logistics, safety, and sustainability.

Proof in Market

Case studies make the impact tangible. A dairy alternative brand extended shelf life from 14 days to 9 months and cut logistics costs by 18%—read the aseptic packaging case study. To see where this system shines, check the best uses of aseptic packaging across beverages, baby food, healthcare, and more.

Ready to size your project? Use our fast estimator and map a path from pilot to scale.