Introduction

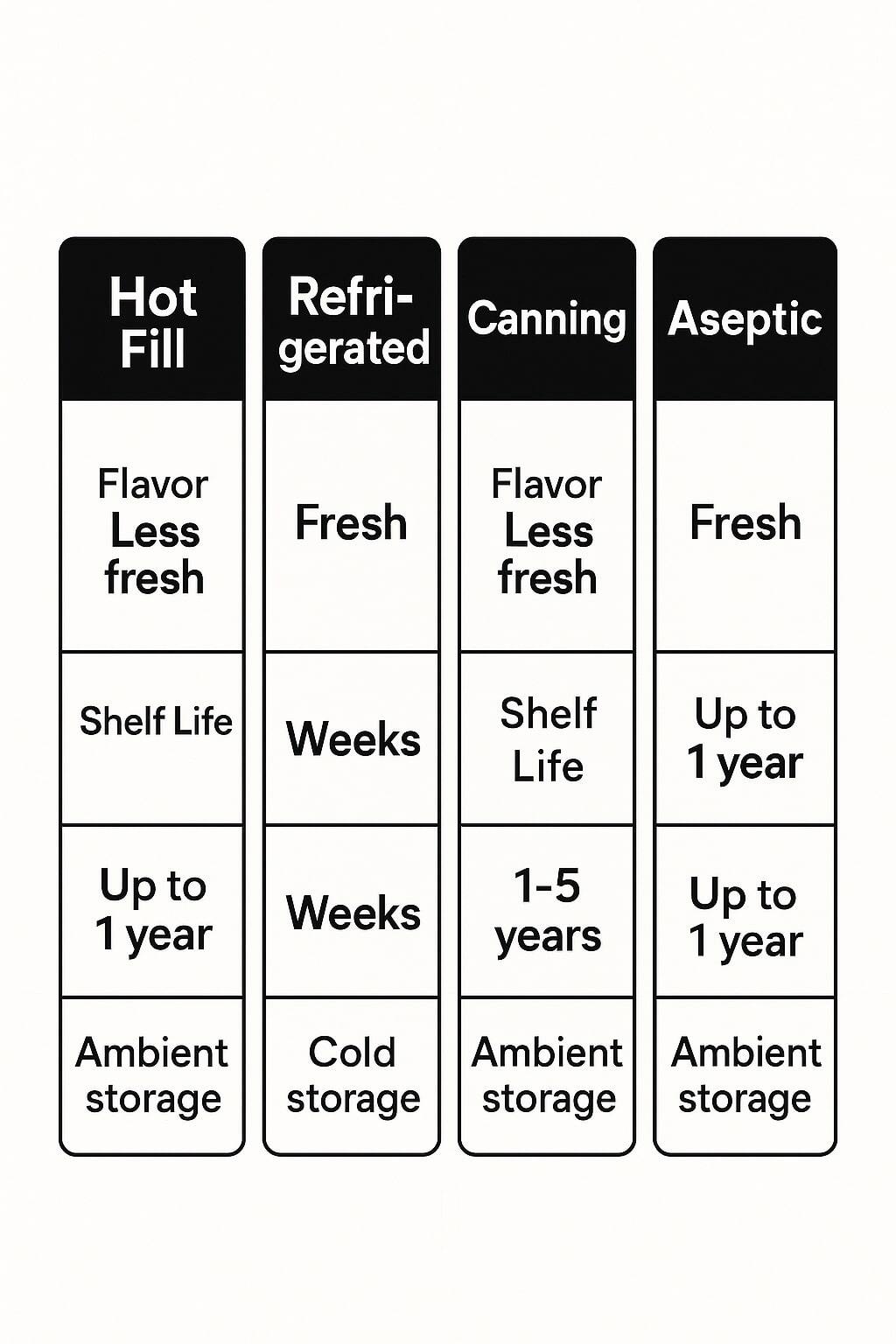

Aseptic packaging excels in categories where freshness, shelf life, and safety are critical. From beverages to bulk foodservice, aseptic is a long-term strategy for growth and global expansion. For mechanics of the process, see our step-by-step guide.