Say what you will about our US government and its incompetence at times, I for one will go on record as applauding one agency in particular and that is the FDA, the Food and Drug Administration. Just this week alone we saw recalls (voluntary or enforced) for reports and confirmation of listeria and salmonella from companies such as Sabra Dipping Company, Blue Bell Creameries, and Texas Star Nut and Food Company. It seems that every single week there are massive “alerts” that turn into full-fledged recalls. What can we learn from this most recent hummus recall? Your packaging matters and shouldn’t be just an afterthought.

Say what you will about our US government and its incompetence at times, I for one will go on record as applauding one agency in particular and that is the FDA, the Food and Drug Administration. Just this week alone we saw recalls (voluntary or enforced) for reports and confirmation of listeria and salmonella from companies such as Sabra Dipping Company, Blue Bell Creameries, and Texas Star Nut and Food Company. It seems that every single week there are massive “alerts” that turn into full-fledged recalls. What can we learn from this most recent hummus recall? Your packaging matters and shouldn’t be just an afterthought.

Let me be clear, in these particular instances the retail packaging that was used has not been called into question (yet), but all too often companies fail to think about their retail packaging until the last minute. They’ll obsess about the ingredients and raw materials they use but have spent little or no time considering all the elements their products will need to withstand once it is made. For example, Sabra hummus has gone from a cool environment where it was blended to refrigerated then possibly ambient (before being placed on a store shelf) which is back to refrigerated. Once it’s purchased it goes into a shopping cart, a hot car trunk (depending on the area it was sold in) back to a kitchen counter, then maybe a fridge or maybe it sits out and is consumed immediately (our grocery just had a display of Sabra on ice outside of the deli…and it was sitting in some ice and some “cold water” by the time I got there.

What can help preserve not just the product but its consistency, taste and aroma better than the packaging that contains it?

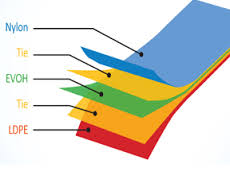

Flexible pack aging is made from layers of laminated barrier film where each layer serves a purpose. There really is a science behind the film structures used and the product they are containing. (SEE DIAGRAM) Some layers are for more for barrier and huge temperature swings (like Sabra or even Blue Bell) while others are for puncture and UV ray protection so sunlight doesn’t degrade or spoil the contents. The most important layer is the innermost or sealant layer…which MUST be made with FDA approved food packaging film. This is the layer that will come into contact with the product, this is the layer that when the packaging is heat sealed closed MUST stay sealed to prevent air from attacking the product. Air is the enemy with flexible packaging and this sealant layer of FDA approved food packaging must not be skimped or trivialized.

aging is made from layers of laminated barrier film where each layer serves a purpose. There really is a science behind the film structures used and the product they are containing. (SEE DIAGRAM) Some layers are for more for barrier and huge temperature swings (like Sabra or even Blue Bell) while others are for puncture and UV ray protection so sunlight doesn’t degrade or spoil the contents. The most important layer is the innermost or sealant layer…which MUST be made with FDA approved food packaging film. This is the layer that will come into contact with the product, this is the layer that when the packaging is heat sealed closed MUST stay sealed to prevent air from attacking the product. Air is the enemy with flexible packaging and this sealant layer of FDA approved food packaging must not be skimped or trivialized.

Here are some tips when packaging your product for retail

- Think about the end first.

- Spend time analyzing what environments your product will need to withstand and develop your packaging accordingly.

- Is it made cold, shipped in warm truck, back to a freezer, then ambient, etc? This is YOUR product, be aware of what it will need to be protected from and count on your packaging to deliver!

- Use only FDA approved food packaging and get it certified.

- Your supplier should be more than willing to show they are using a food grade sealant layer

- Don’t allow your Marketing department to decide what retail packaging to use.

- To be clear, I’m not suggesting Marketing not have a say, but what I am saying is that Marketing will look at colors and shades of colors and NOT what is needed to protect your product. Get input from your packaging professional and your Operations department as well.

- Work with your packaging professional for guidance and direction BEFORE the last minute.

- I don’t say this to be cute or funny. Your packaging professional should be a part of your packaging design from the beginning. There are endless combinations of FDA food packaging film structures. They know film structures and temperature limits and frankly should know your product pretty well. With this information they can suggest cost effective films to use so you get what your product needs for protection at the right price point and cost structure you need.

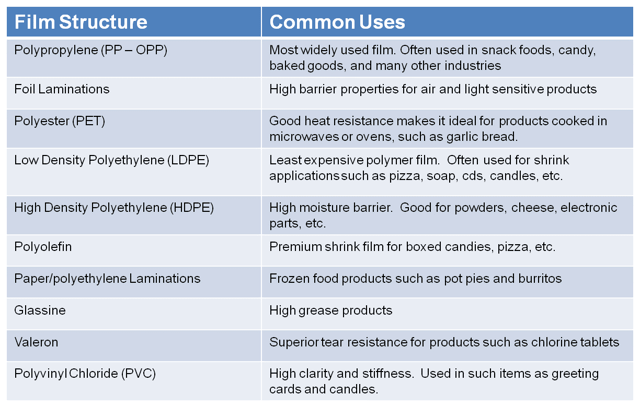

Here are some common film structures for flexible packaging you may find helpful:

Again, in these particular situations (Sabra hummus recall and Blue Bell ice cream recall) nothing has shown that their packaging had anything to do with the reports of Listeria in their product. However, this serves as a great reminder for all of us who need retail packaging to heed these suggestions and pay attention to not only the FDA reports but to seek out and use only FDA approved food packaging.