What Can Go Wrong—and Why

Most failures trace to seal integrity, under-spec’d films, or misaligned equipment. Fixing root causes early saves rework, scrap, and customer goodwill. For a holistic view of costs and savings, see the pillar.

Prevent leaks, downtime, and reputation hits with the right films, seals, and equipment settings. For context and benefits, start with the pillar guide.

ESTIMATE MY PROJECT COST

Most failures trace to seal integrity, under-spec’d films, or misaligned equipment. Fixing root causes early saves rework, scrap, and customer goodwill. For a holistic view of costs and savings, see the pillar.

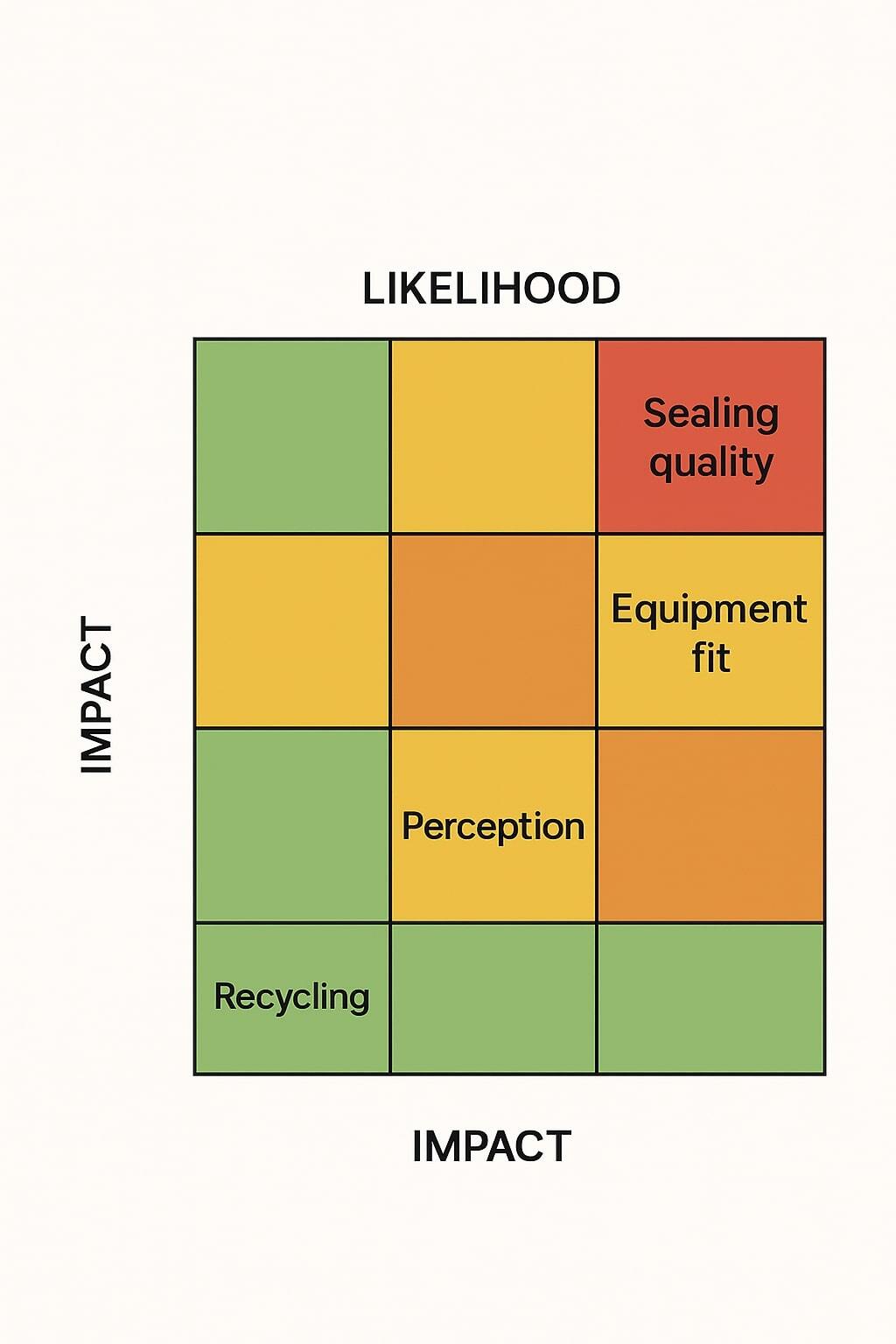

Quantify tradeoffs using the cost model outlined in the cost breakdown and pillar.

A nutrition drink brand cut leak rates from 4% to <0.2% after optimizing laminate selection and seal parameters, while boosting line speed by 25%.

See more examples in case studies and baseline benefits in the pillar.

Avoid costly trial-and-error by auditing films, seals, and equipment upfront—then explore the full economics in the pillar guide.

ESTIMATE MY PROJECT COST