Why Pouches Deliver a Financial Edge

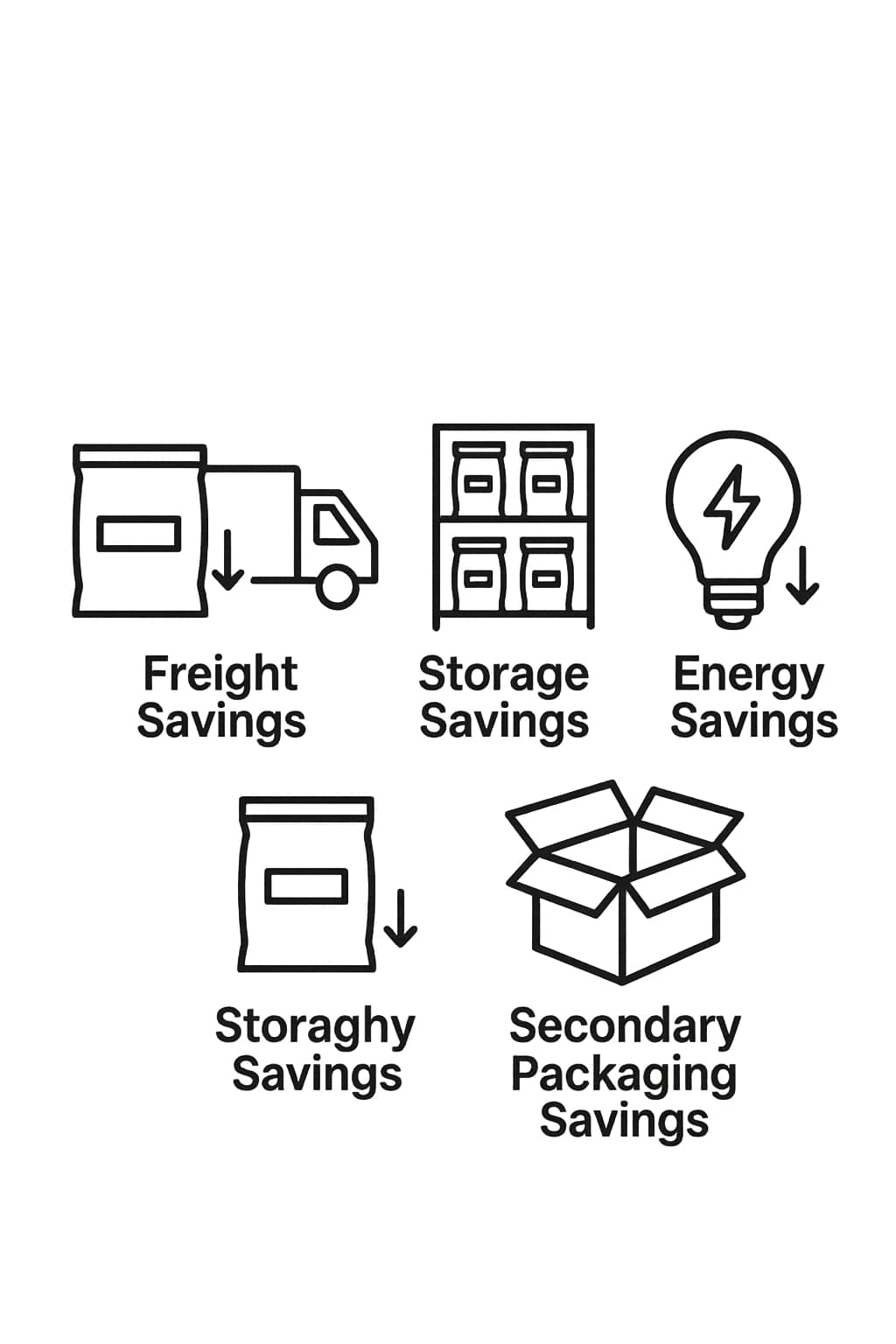

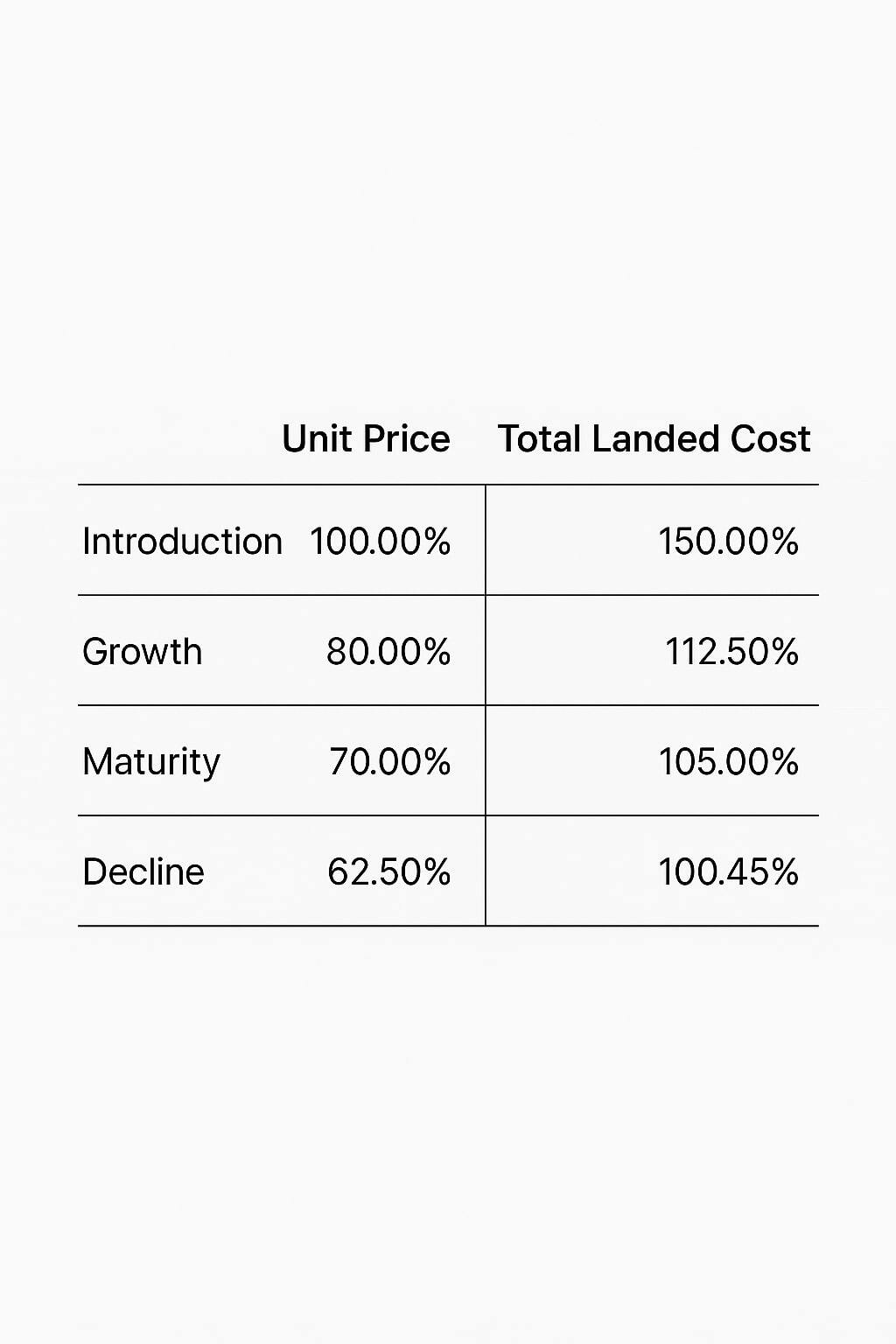

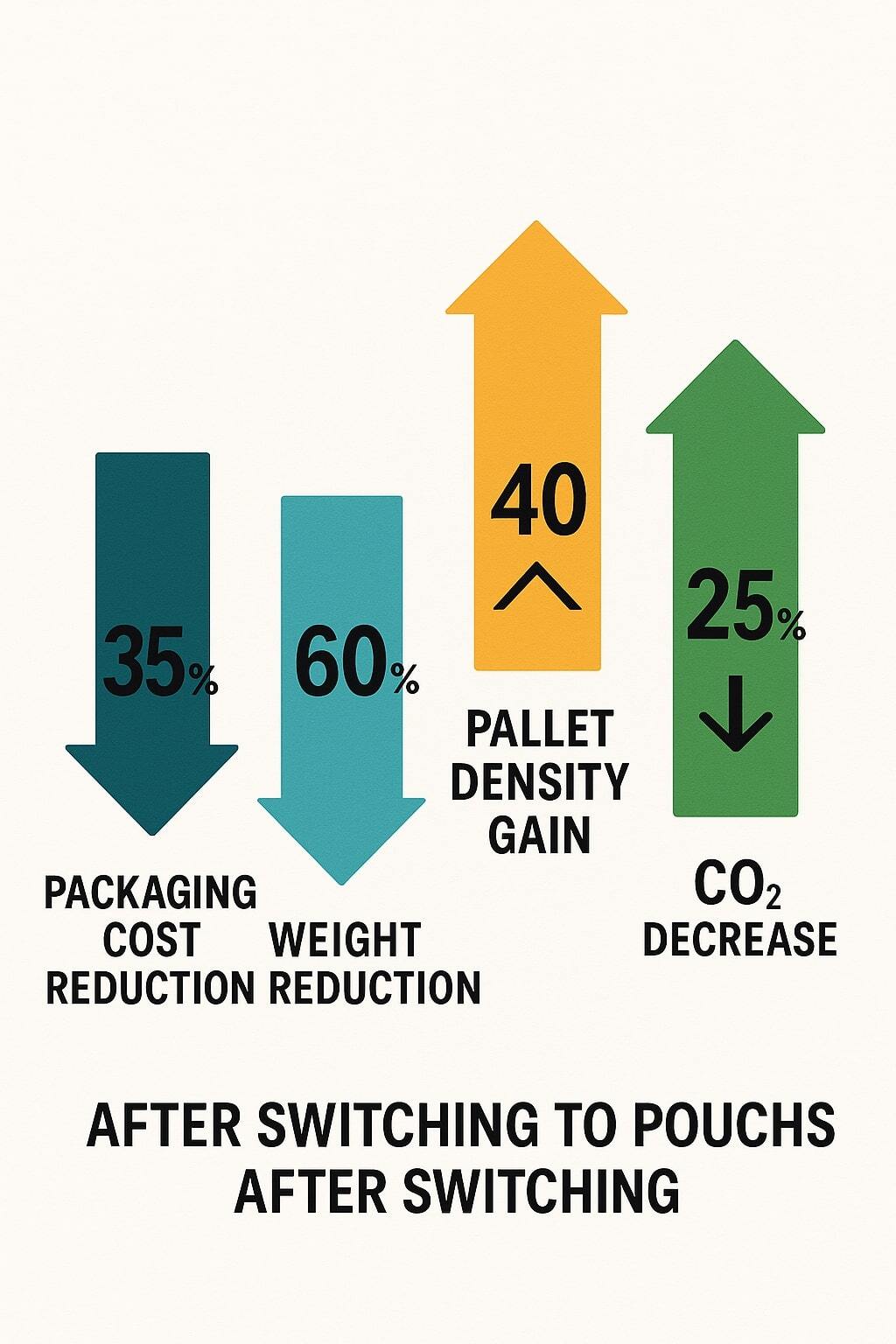

Compared to bottles or cans, flexible liquid pouches use less material, store flatter, and ship lighter. Those efficiencies compound across millions of units—turning packaging into a competitive advantage. Explore the macro picture in the pillar guide.