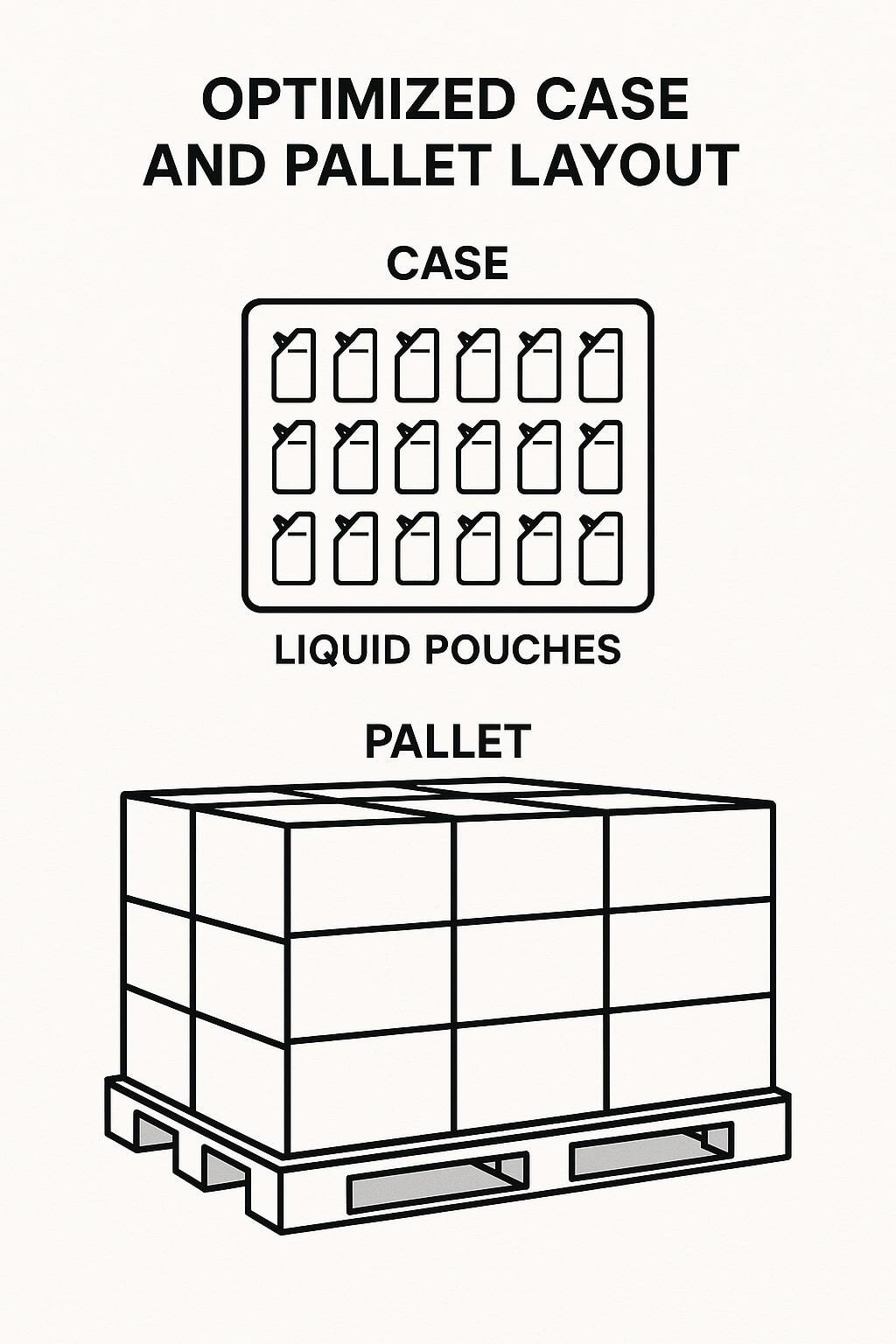

Design for Pallet & Case Density

Right-size height, width, and gusset to maximize units per layer and per pallet. Model case packs to minimize void and corrugate while maintaining protection.

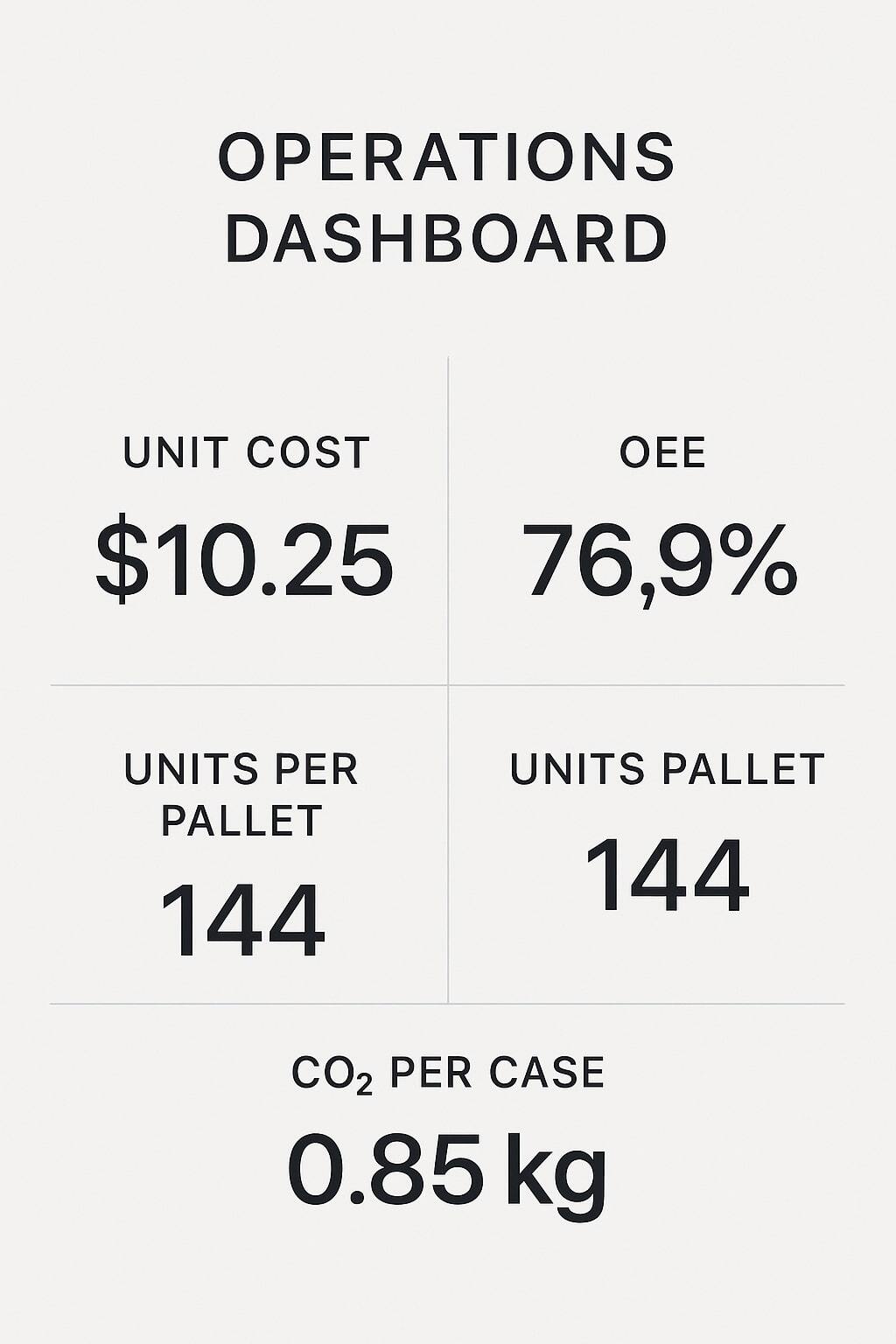

For the cost rationale, see the cost breakdown and the pillar.