Introduction

Aseptic packaging delivers shelf life and global reach—but only with disciplined operations. Use this page with the pillar page to plan a robust implementation.

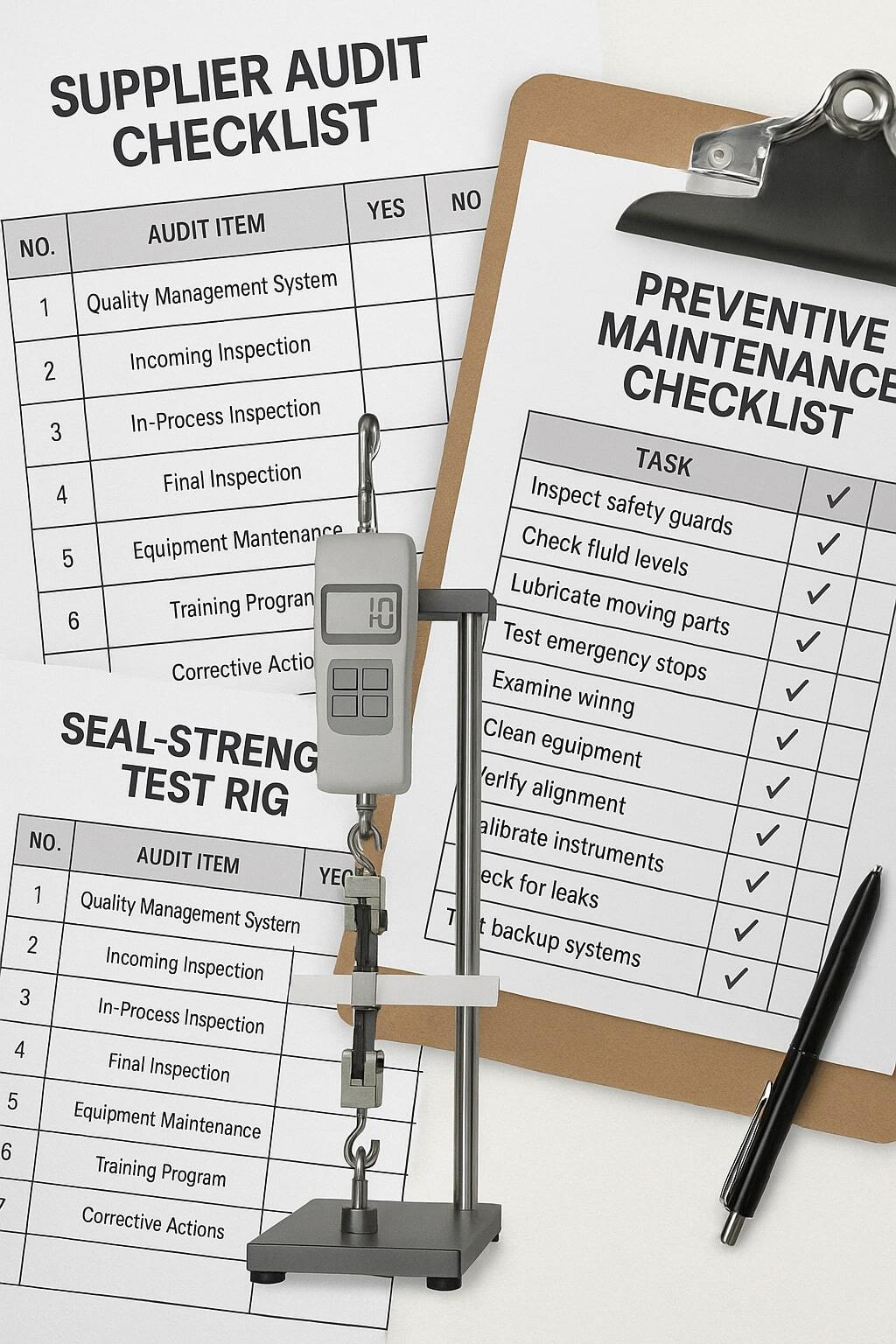

Understand investment, sterilization, compliance, and training challenges—then see how to mitigate each in the step-by-step pillar guide.

ESTIMATE MY PROJECT COSTAseptic packaging delivers shelf life and global reach—but only with disciplined operations. Use this page with the pillar page to plan a robust implementation.

Upfront equipment, education campaigns, and QA testing add cost—yet reductions in spoilage, refrigeration, and returns can outweigh them. See cost levers in the Cost of Aseptic Packaging page and the pillar guide.

Traditional: shorter shelf life, higher spoilage, refrigerated logistics. Aseptic: complex equipment and compliance, but reduced waste and ambient logistics once stabilized.

Global Juice Manufacturer: Standardized sterilization, improved training (operator errors down 60%), achieved compliance in 12 markets, and cut logistics costs by 25% with ambient shipping.

Connect the dots back to process steps on the pillar.

Map your risk plan alongside the full process—return to the Aseptic Step-by-Step Guide and get a tailored estimate.

ESTIMATE MY PROJECT COST