Introduction

Aseptic packaging can look expensive—until you model shelf life, logistics, and spoilage. This overview breaks down the cost drivers and links back to the pillar page for a complete systems view.

Understand equipment, materials, volume, and product category—and why total cost of ownership often favors aseptic systems. Explore the full process on the Aseptic Packaging Step-by-Step Guide.

ESTIMATE MY PROJECT COSTAseptic packaging can look expensive—until you model shelf life, logistics, and spoilage. This overview breaks down the cost drivers and links back to the pillar page for a complete systems view.

See how these fit into the process in the pillar guide.

Balance risks with a phased approach and supplier partnerships—see risk planning on the pillar page.

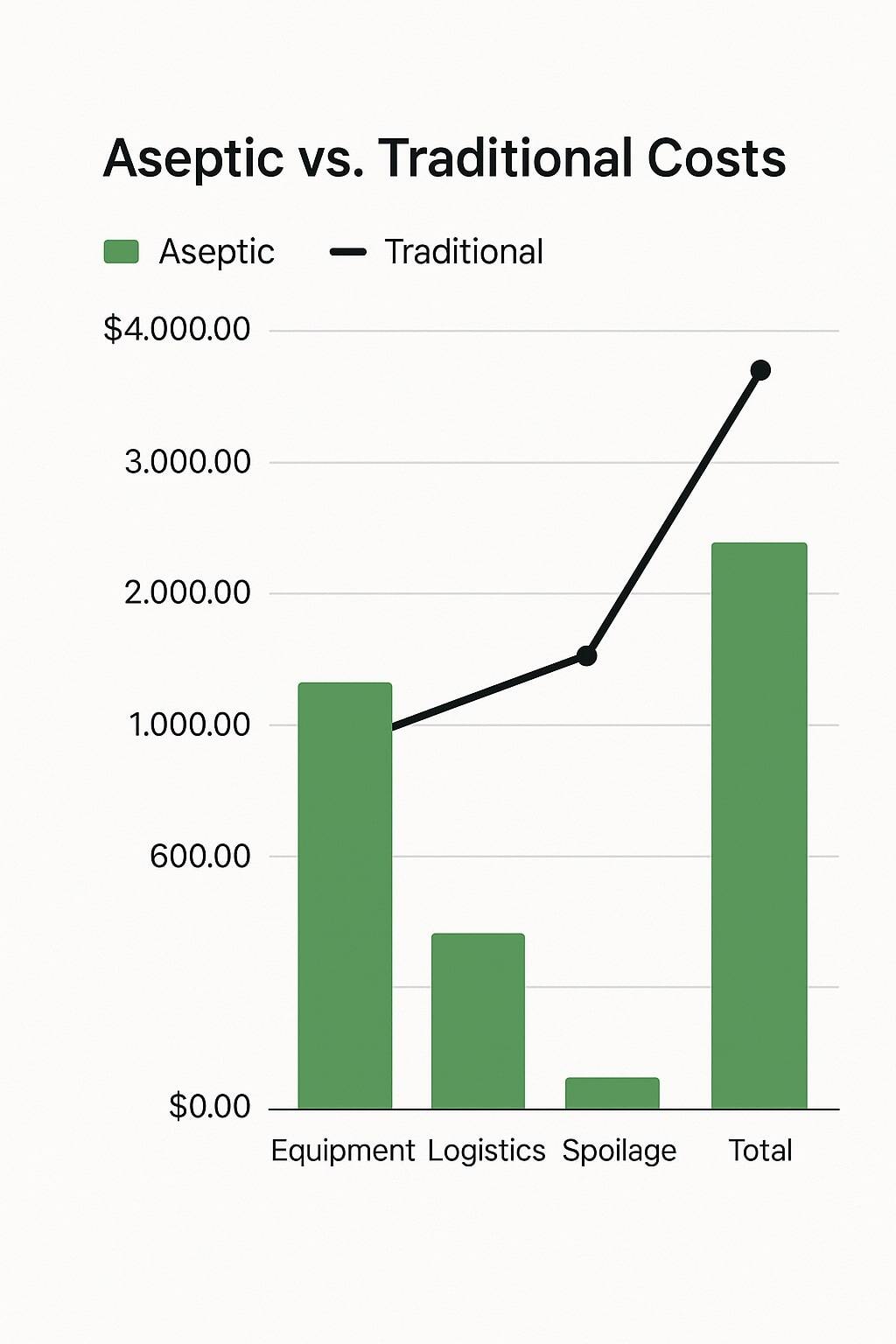

Aseptic carries higher upfronts but often wins on total cost of ownership by eliminating cold chain and reducing spoilage. For a deeper apples-to-apples view, revisit the step-by-step pillar.

Soup Manufacturer: Cut refrigeration by 40%, extended shelf life to 9 months, trimmed logistics by 22%, and entered export markets—payback in 18 months.

See broader outcomes across categories in the pillar’s case study highlights.

Expand your cost model with process context on the pillar page.

Build a cost model tailored to your product—read the full Aseptic Step-by-Step Guide then get a fast estimate.

ESTIMATE MY PROJECT COST