A Balanced View of Aseptic

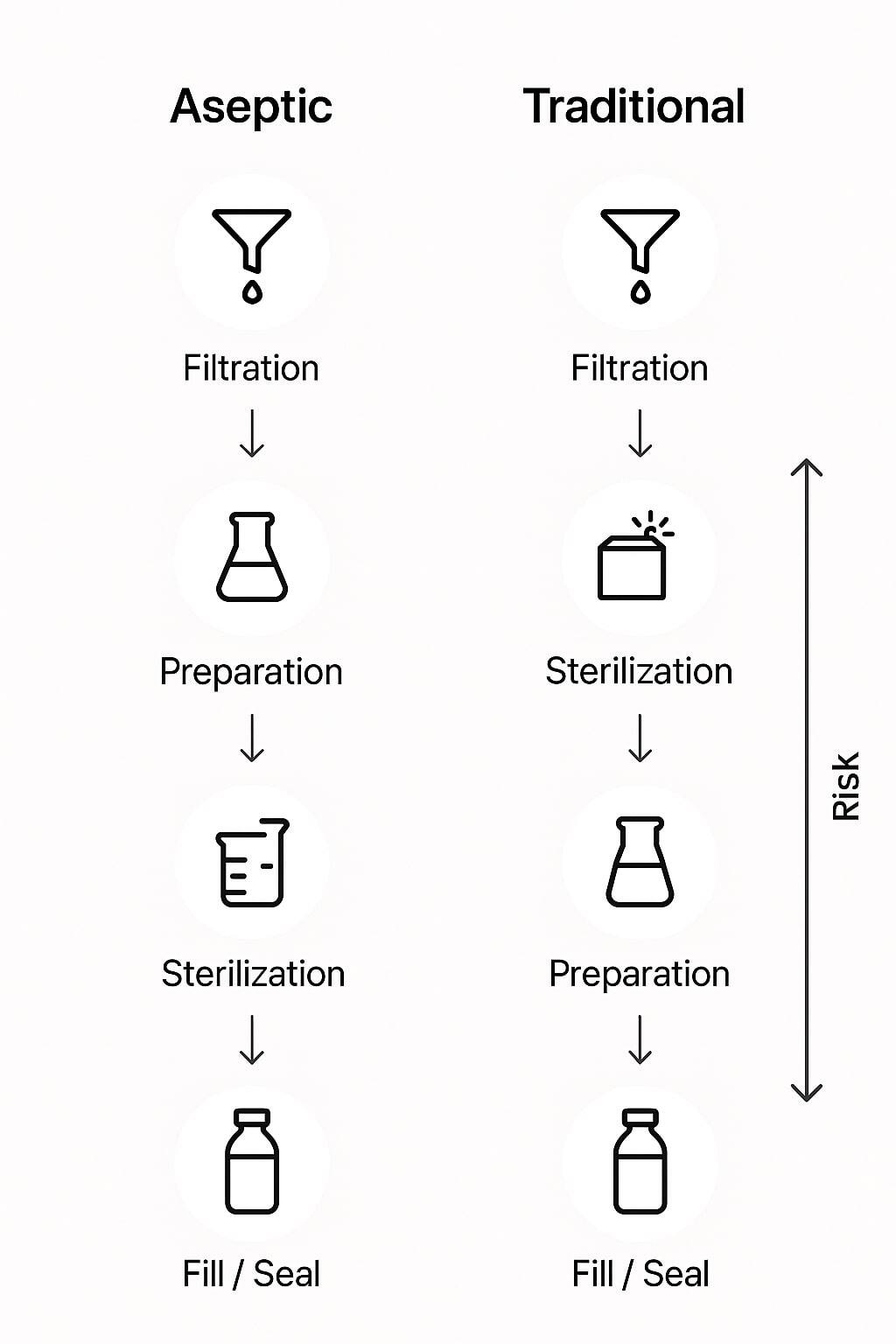

Aseptic packaging is widely recognized for its cost, sustainability, and shelf-life advantages—but it also presents unique challenges that companies must carefully manage. Understanding these potential risks early helps manufacturers prepare for smoother implementation and avoid costly missteps. For context on benefits, see the advantages of aseptic packaging pillar.