Introduction

Aseptic packaging has revolutionized how liquid and semi-liquid products are processed, filled, and distributed. Unlike traditional packaging methods that rely on heat sterilization after filling, aseptic systems sterilize both the product and the packaging separately, combining them in a sterile environment. This innovation offers extended shelf life, reduced energy use, and improved sustainability—without the need for preservatives or refrigeration.

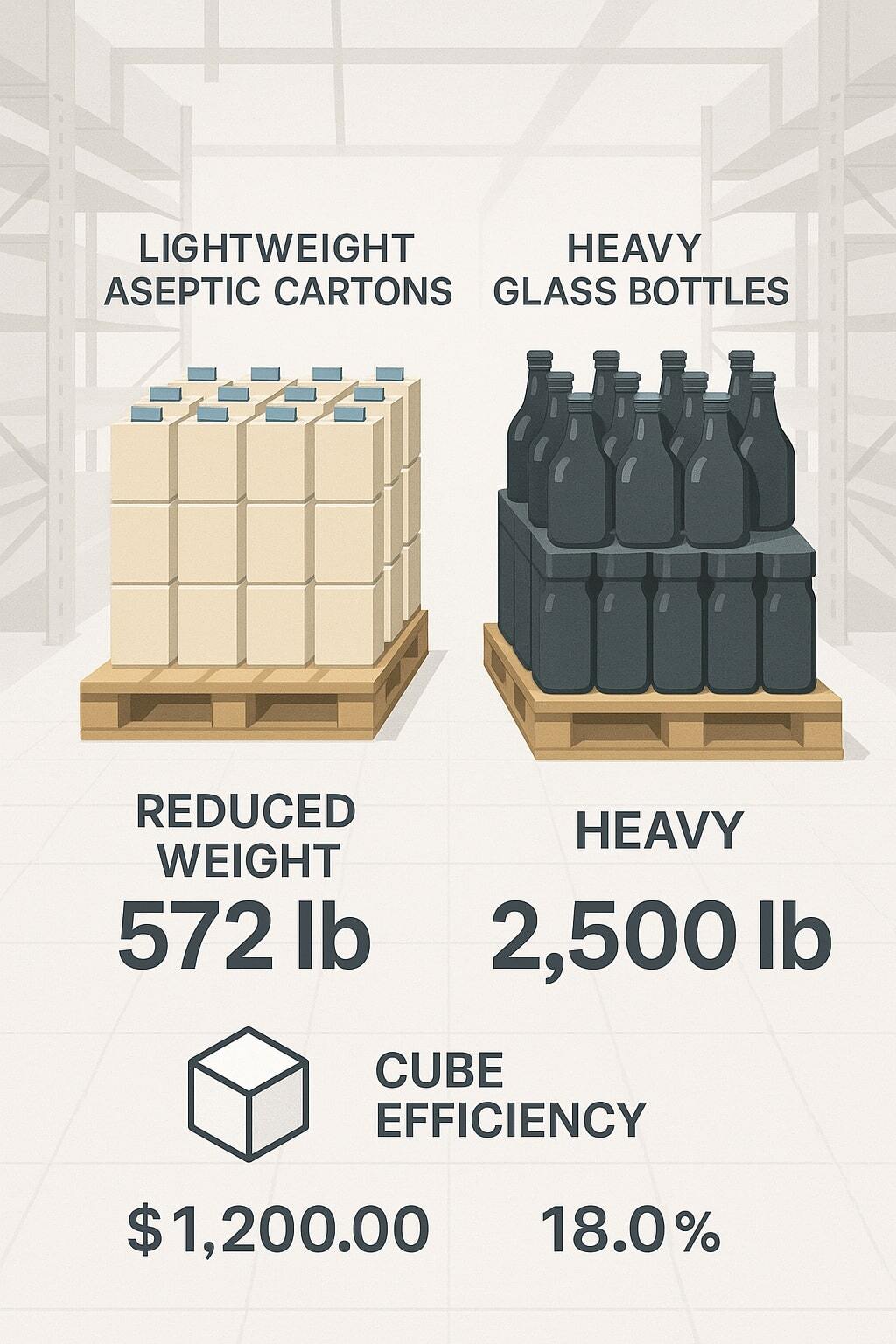

From beverages to soups and dairy alternatives, brands worldwide are moving away from traditional cans and glass jars in favor of aseptic formats that meet today’s efficiency, cost, and sustainability demands.