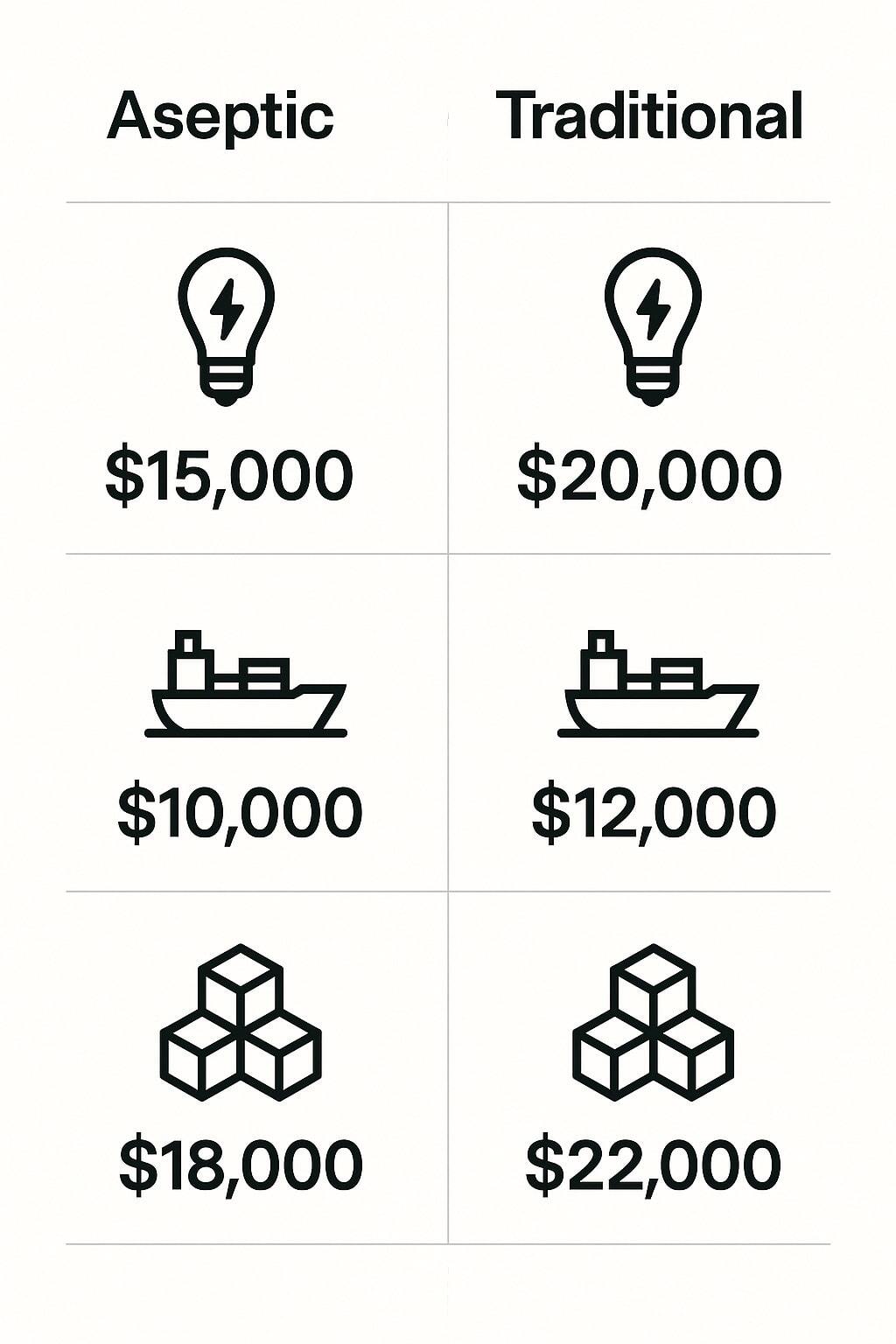

Why Aseptic Saves Money

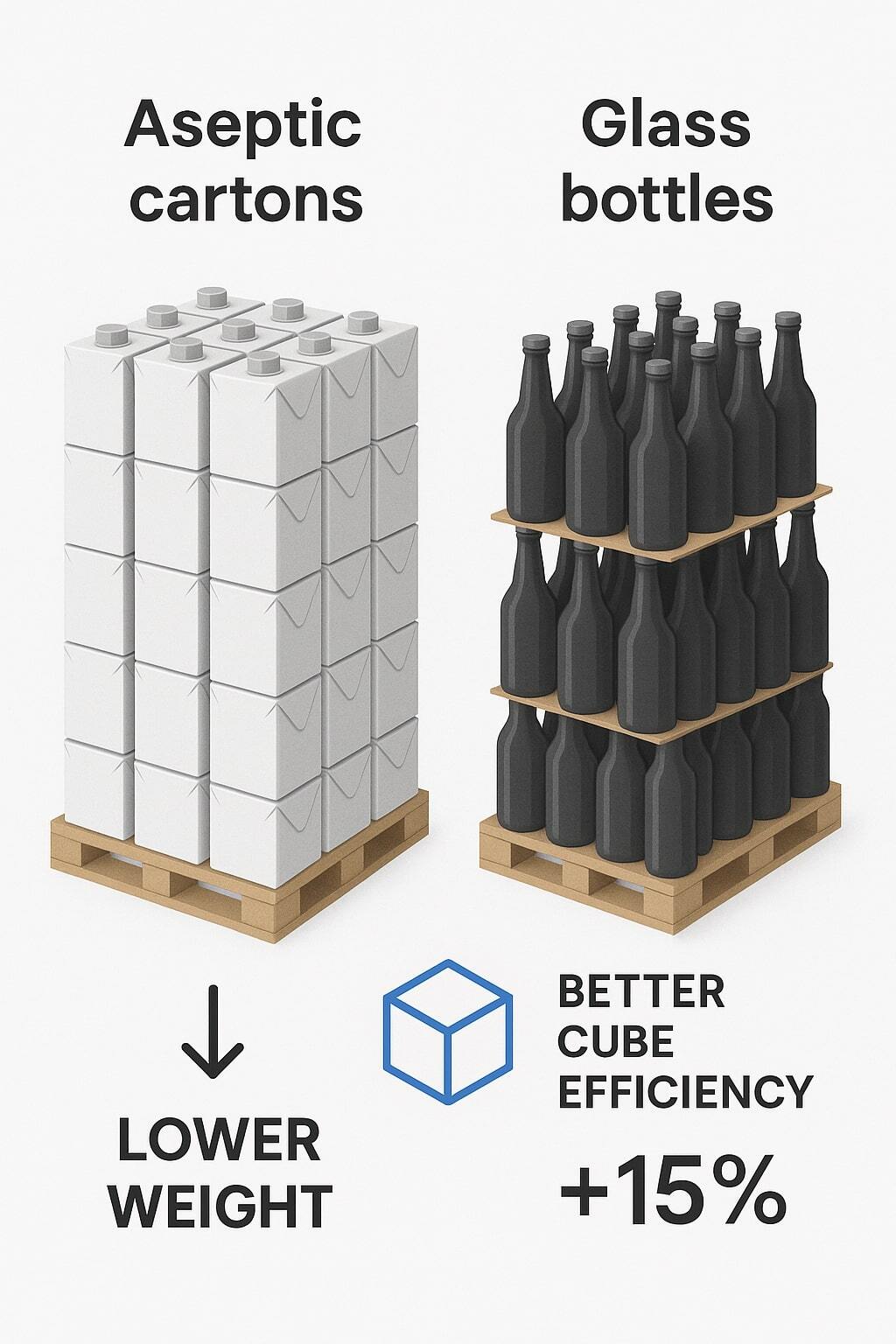

Cost is one of the strongest reasons brands are switching from traditional packaging to aseptic systems. While traditional glass, metal, or rigid plastic containers rely on heat sterilization, refrigeration, and heavy materials, aseptic packaging uses lightweight, shelf-stable materials that require no cold chain.

For the full picture of benefits, see the advantages of aseptic packaging pillar page.