How They Differ

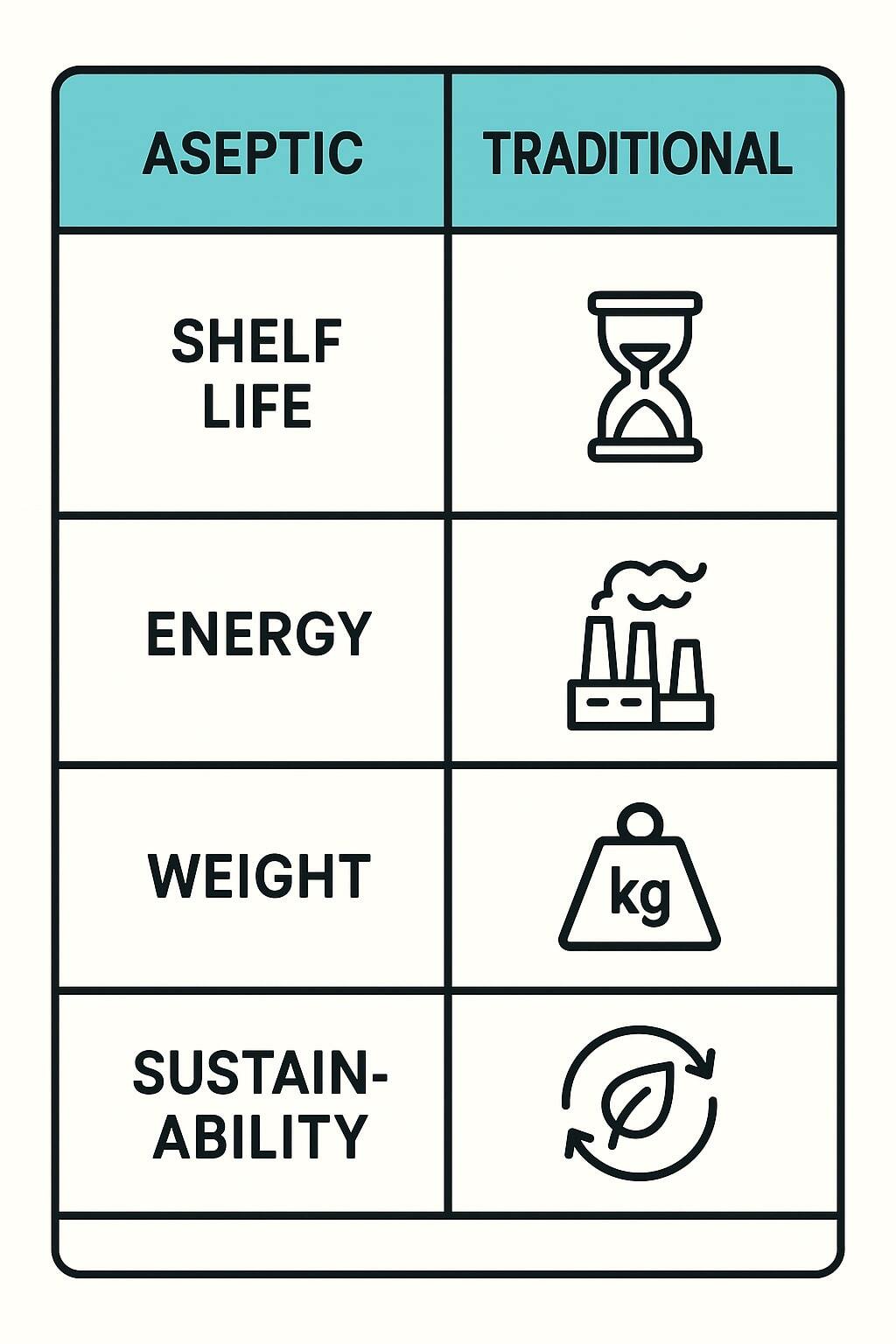

Traditional systems rely on post-fill sterilization and heavier materials, while aseptic packaging sterilizes product and container separately before sealing in a sterile environment. The result is lighter shipments, longer shelf life, and lower energy use—without refrigeration. For context on overall benefits, see the advantages pillar.