Why MOQ Isn’t Just a Supplier Rule—It’s a Price Strategy

MOQs spread fixed setup over more units, dropping per-pouch cost. For context on all cost levers, review the complete pricing breakdown.

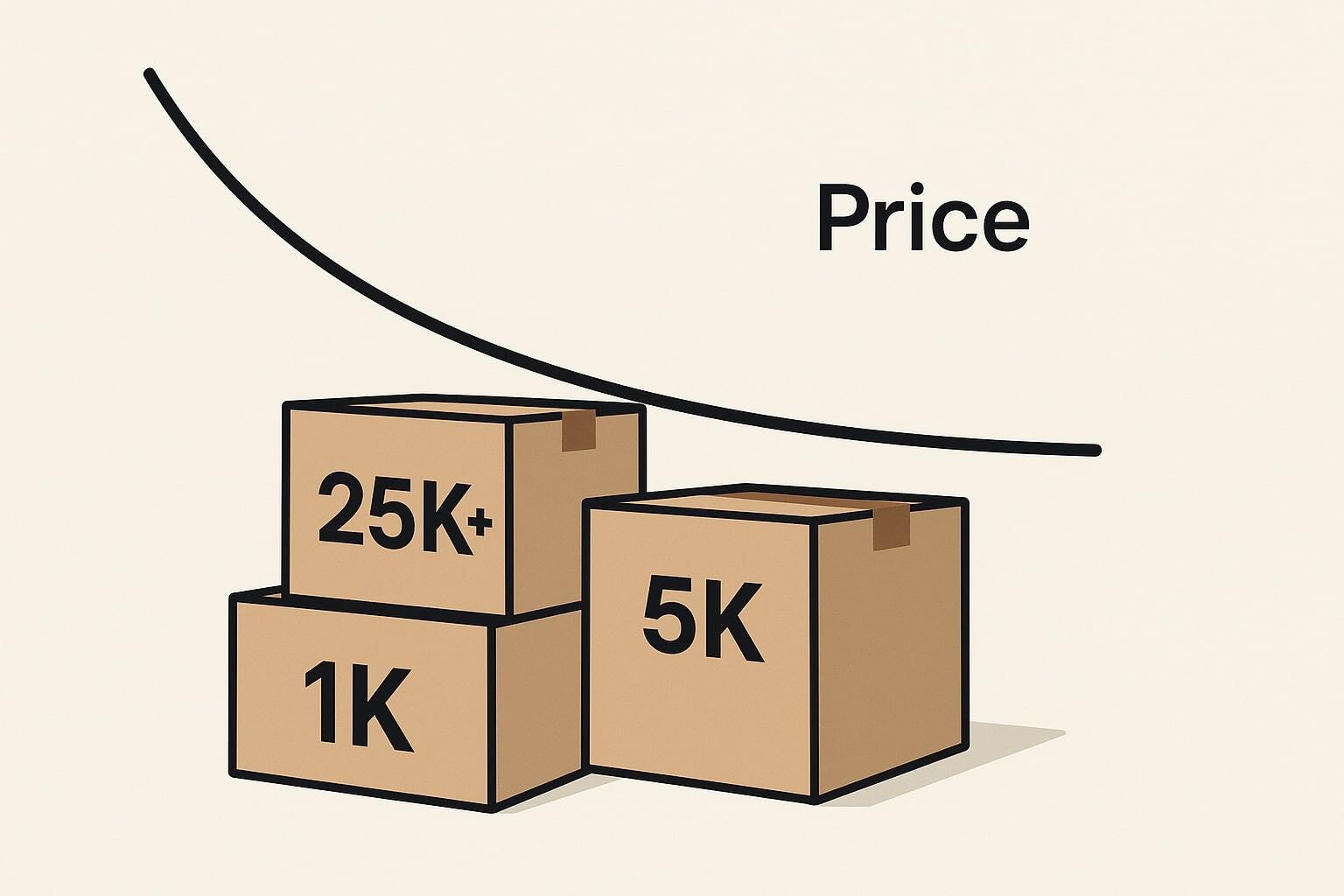

Why MOQs exist, how they change unit price, and when to start small versus scale.

ESTIMATE MY PROJECT COST

MOQs spread fixed setup over more units, dropping per-pouch cost. For context on all cost levers, review the complete pricing breakdown.

Short runs still require full setup, so unit prices are higher at low volumes. See price tiers in the table below.

| Order Qty | Avg Cost Per Pouch | Print Method |

|---|---|---|

| 1,000 | $0.55–$1.00 | Digital |

| 5,000 | $0.25–$0.50 | Flexographic |

| 25,000+ | $0.18–$0.35 | Rotogravure |

Option A—Digital: MOQ 1,000; ~ $0.75 each; 2,500 units ≈ $1,875.

Option B—Flexo: MOQ 5,000; ~ $0.35 each; 5,000 units ≈ $1,750 + ~$400 plates. If you’ll use the inventory, per-unit and total can be lower.

Ask about MOQ brackets—3,000 may price near 2,000 but unlock better economics. Compare breakpoints in the pillar guide.

| Pouch Type | Typical MOQ |

|---|---|

| Digital Print | 500–1,000 pcs |

| Flexo Print | 5,000–10,000 pcs |

| Gravure Print | 25,000+ pcs |

| Clear Stock | As low as 100 pcs |

Use MOQ strategically to lower cost and scale smart. Consider digital short runs, hybrid stock+custom, bundling SKUs, or scheduled reorders. Cross-check scenarios against the pillar breakdown.