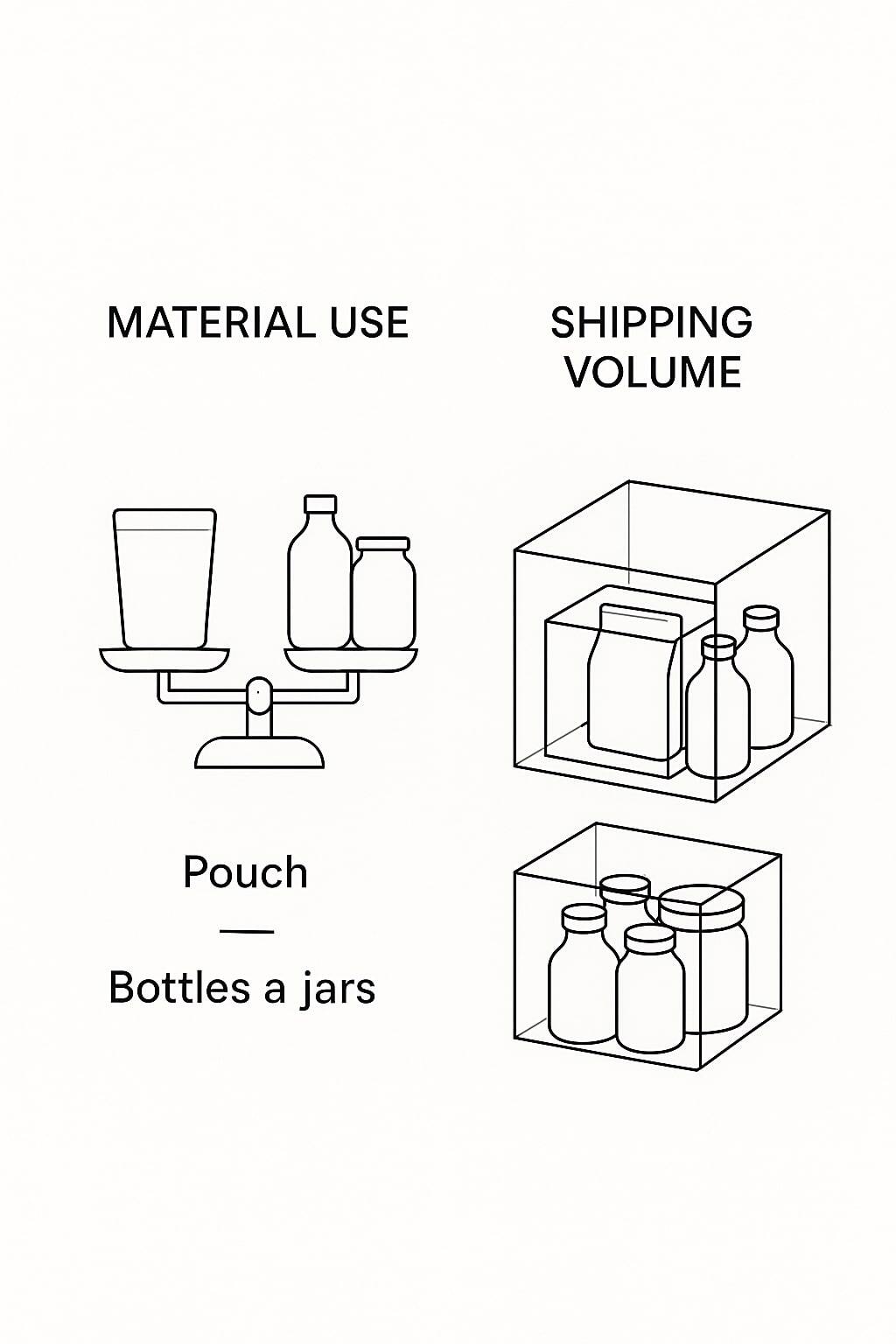

Weight & Volume

- Pouches use up to 70% less plastic.

- Unfilled pouches ship flat—10–15× freight advantage.

Quantify savings in our cost savings guide and see category context in the pillar.

Quantify savings in our cost savings guide and see category context in the pillar.

Resealability improves freshness, spouts and handles improve pour control and portability—areas where rigid formats often fall short.

Learn how to substantiate claims in the risks page and see top applications in Best Uses.

Pouches stand upright and present a large, contiguous printable surface—more room for storytelling and compliance labeling.

Explore more outcomes inside our case studies and in the pillar.