Barrier Protection Concerns

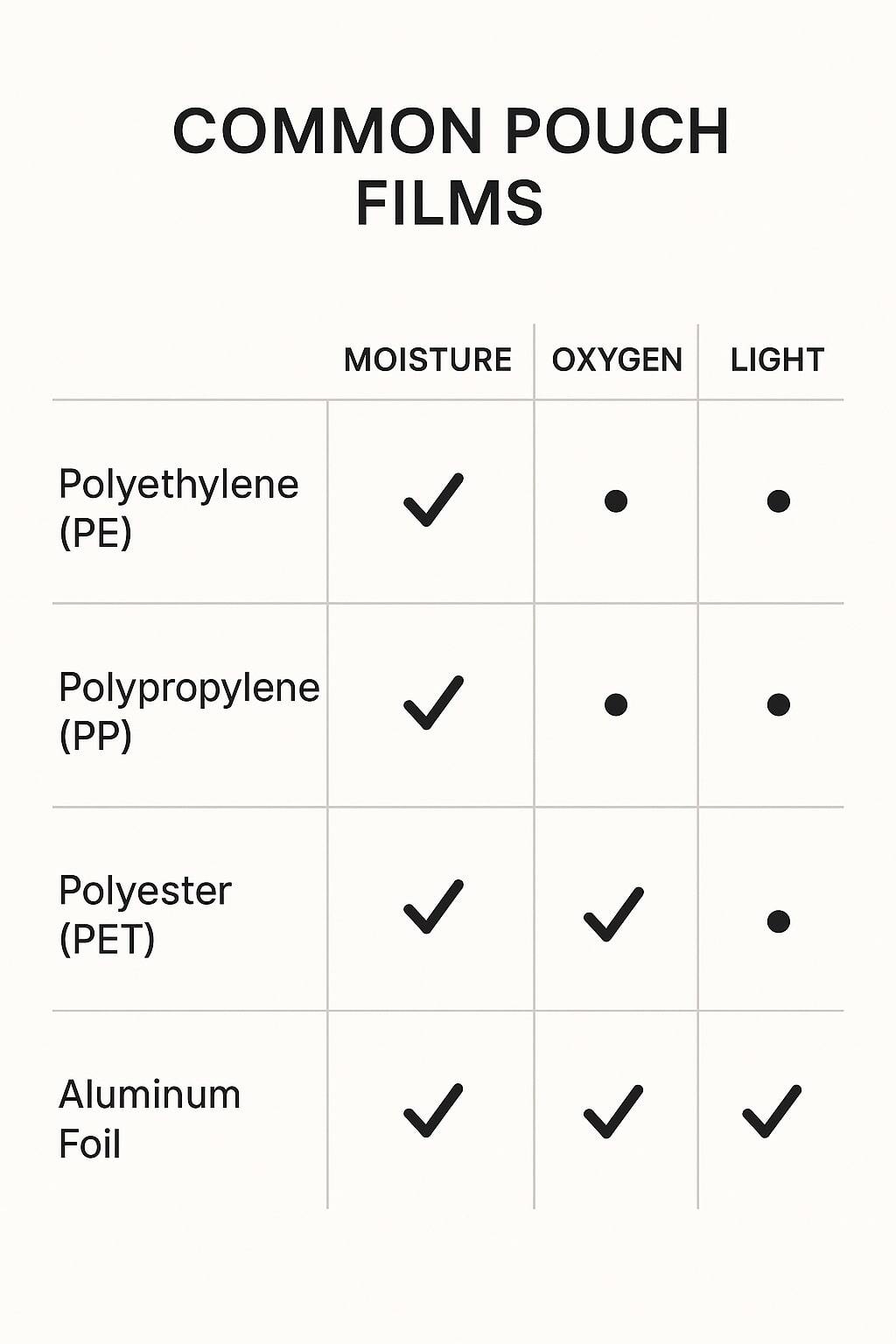

Match film to product needs: moisture for snacks and coffee, oxygen for oils and beverages, and light for UV-sensitive goods. For context by category, review the applications & trends pillar.

Match film to product needs: moisture for snacks and coffee, oxygen for oils and beverages, and light for UV-sensitive goods. For context by category, review the applications & trends pillar.

Compare branding canvas vs rigid in the format comparison and see best-fit categories in Best Uses.

Back claims with certifications and clear labeling. Retailers increasingly require verifiable standards—align claims with actual materials and disposal pathways highlighted in the pillar.

Contrast operational impacts against rigid formats in our comparison and revisit industry nuances in the pillar.

A beverage startup skipped barrier testing; off-flavors and spoilage led to a costly recall. Validate structures before scale and document specifications for operations and retailers.