What to Watch

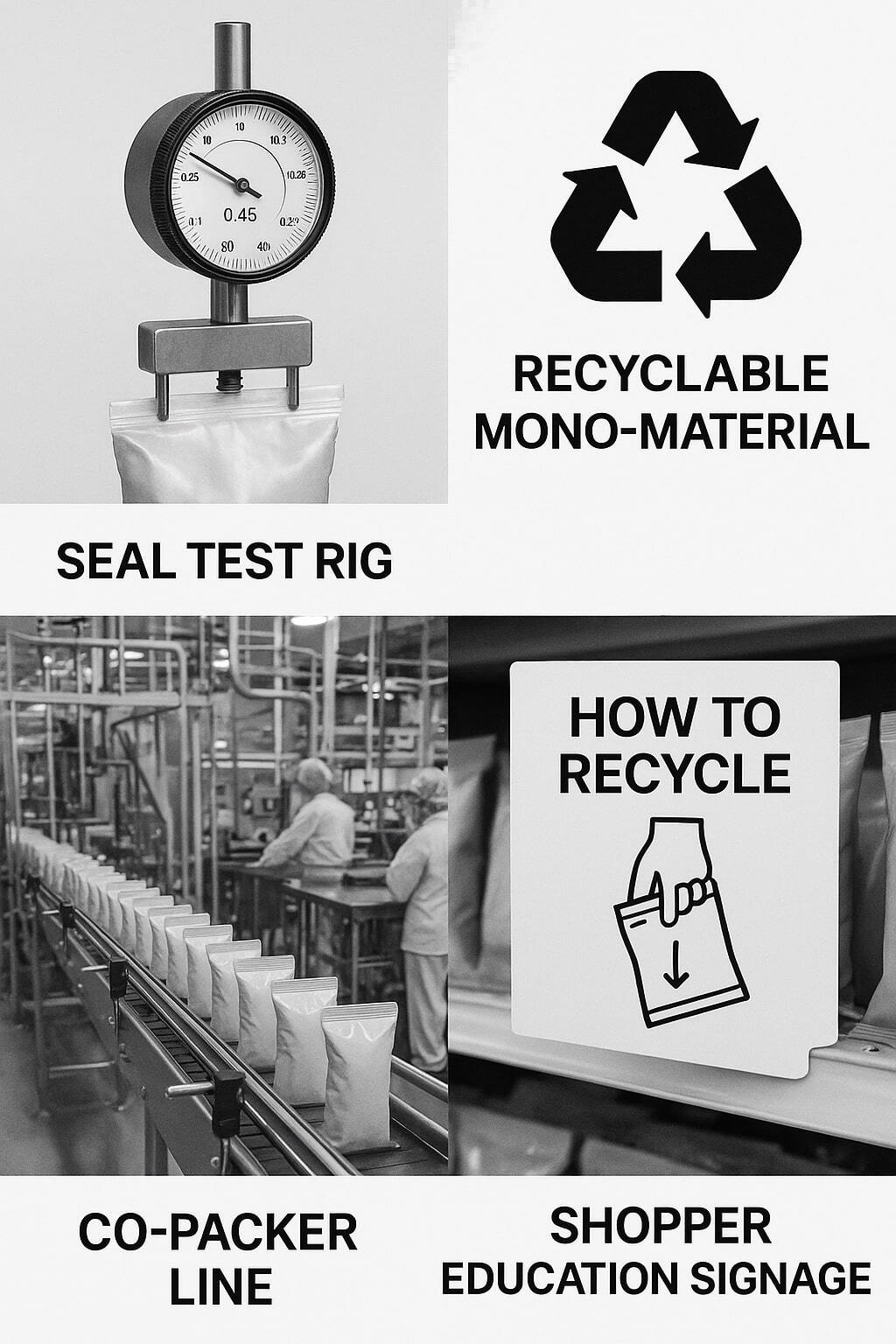

- Filling equipment: evaluate contract packagers vs in-house lines.

- Consumer familiarity: educate where bottles/cartons are entrenched.

- Durability: prioritize seal strength and distribution testing.

- Recycling: mono-material options are growing but vary by region.

See the overall value proposition on the pillar page and compare alternatives in the comparison guide.