Introduction

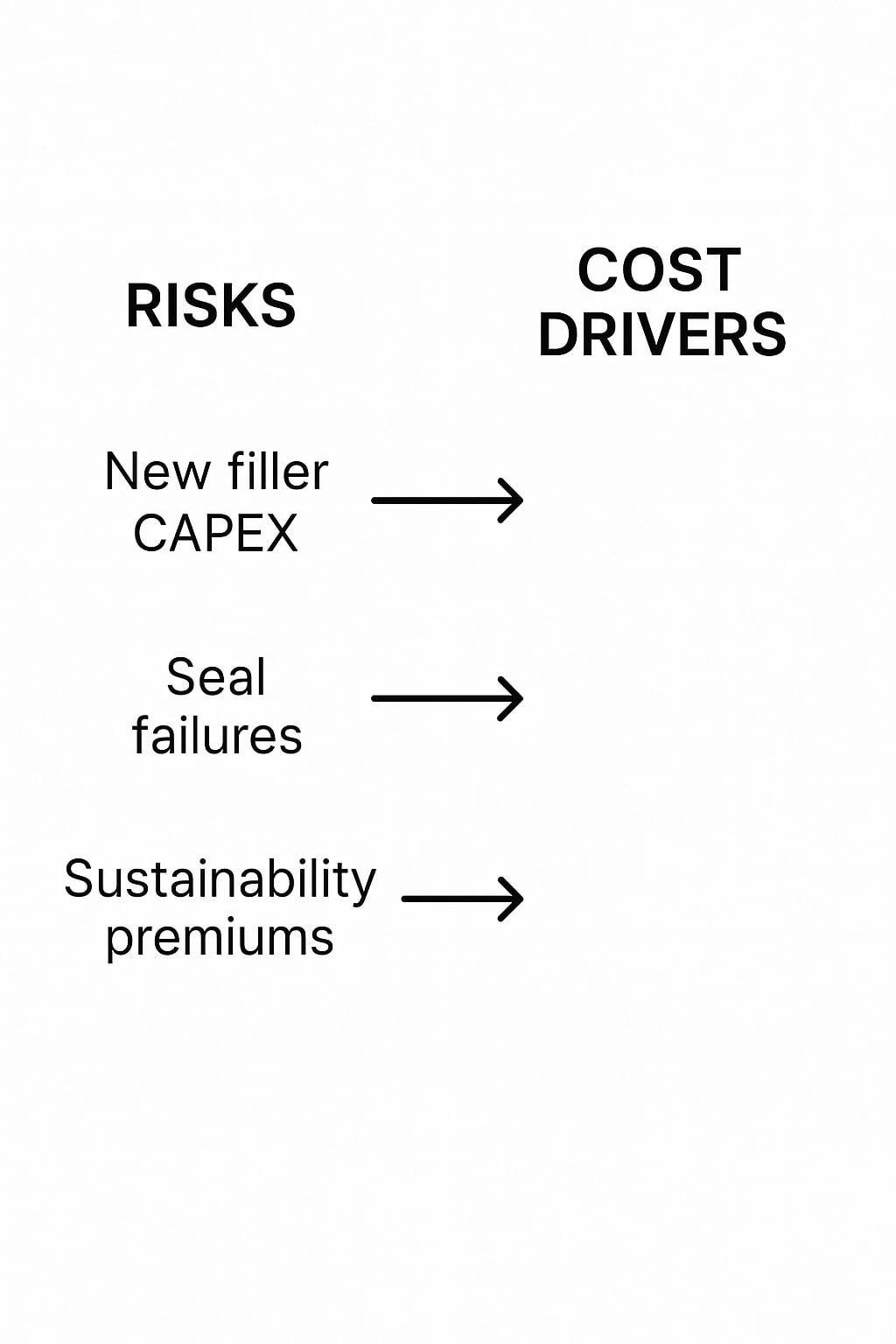

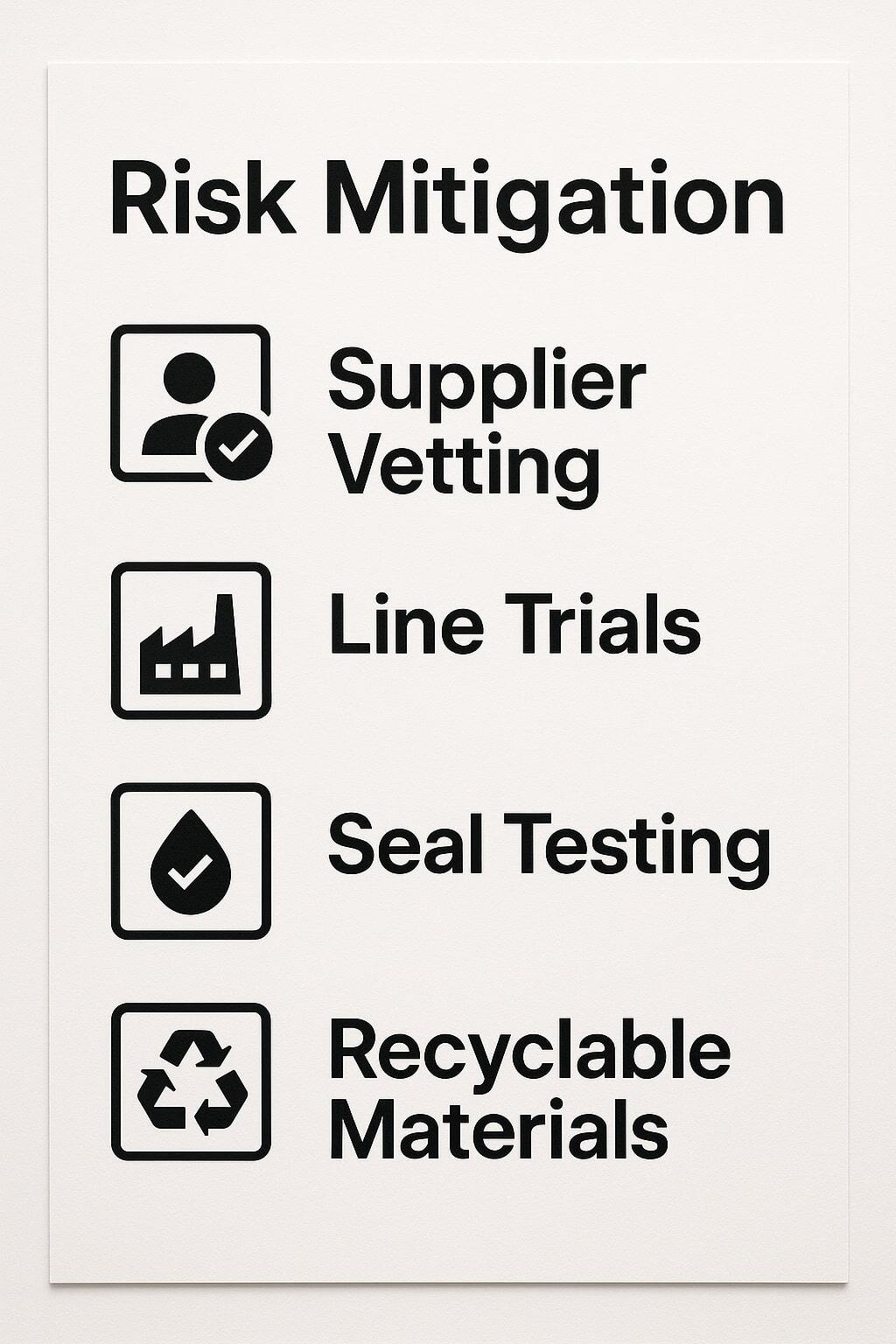

Spouted pouches are versatile, but they come with unique challenges. Brands must evaluate filling line compatibility, spout fitment quality, and recycling goals before switching from rigid packaging. For the fundamentals of the format and its advantages, review the Spouted Pouches pillar.