Introduction

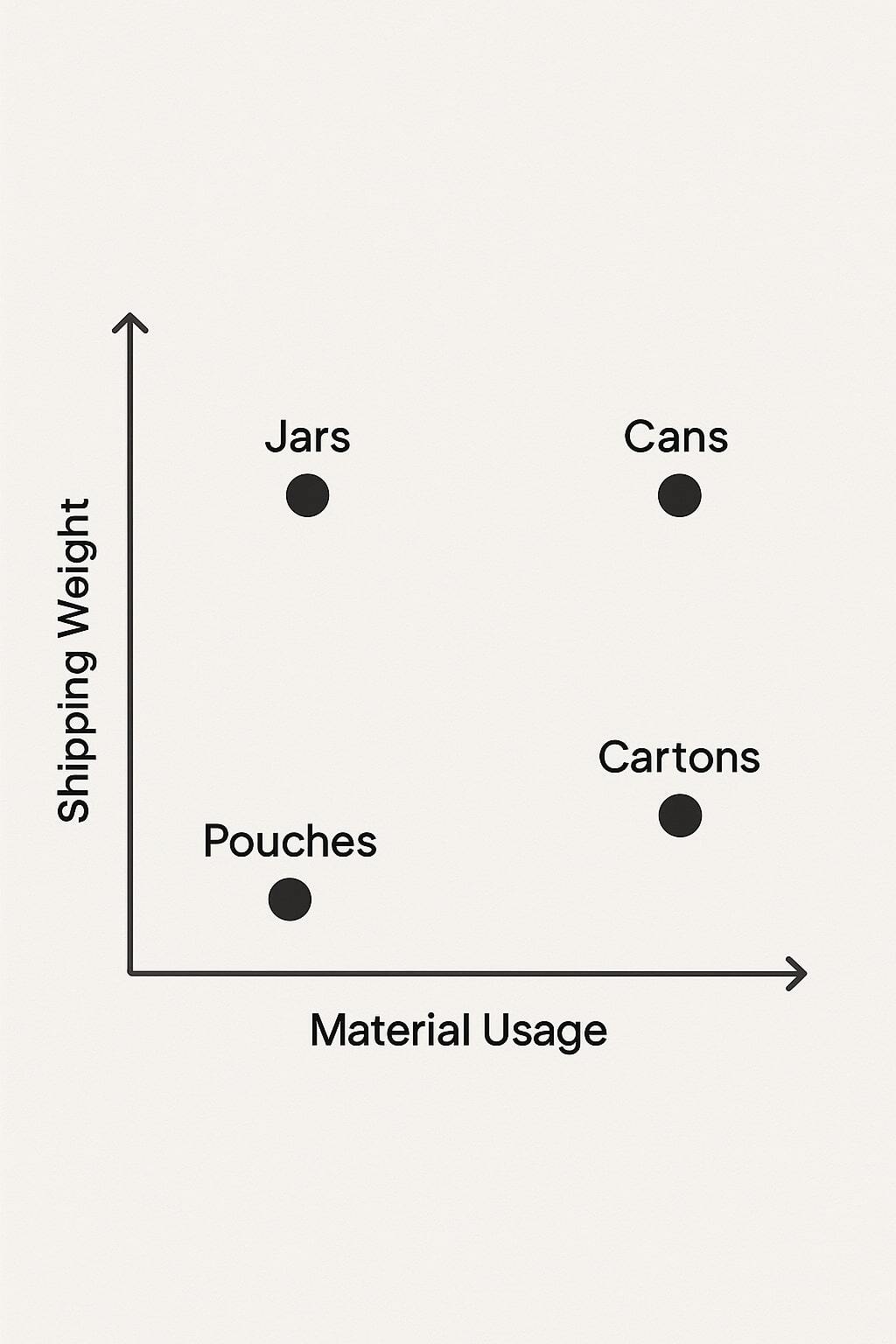

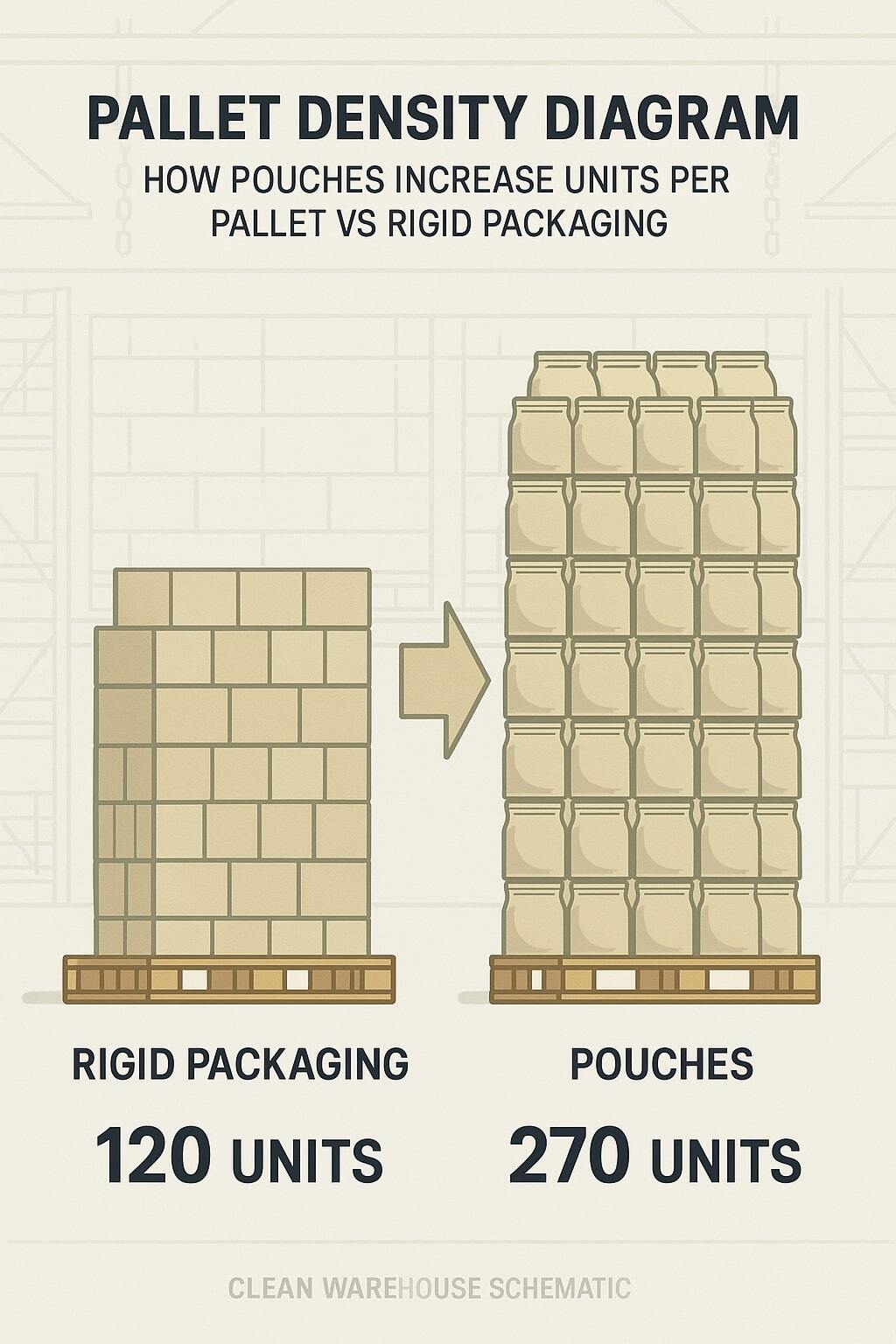

Flexible packaging is growing rapidly in food, but traditional options remain relevant. This page compares cost, performance, sustainability, and perception—then links back to the complete food packaging guide for next steps.

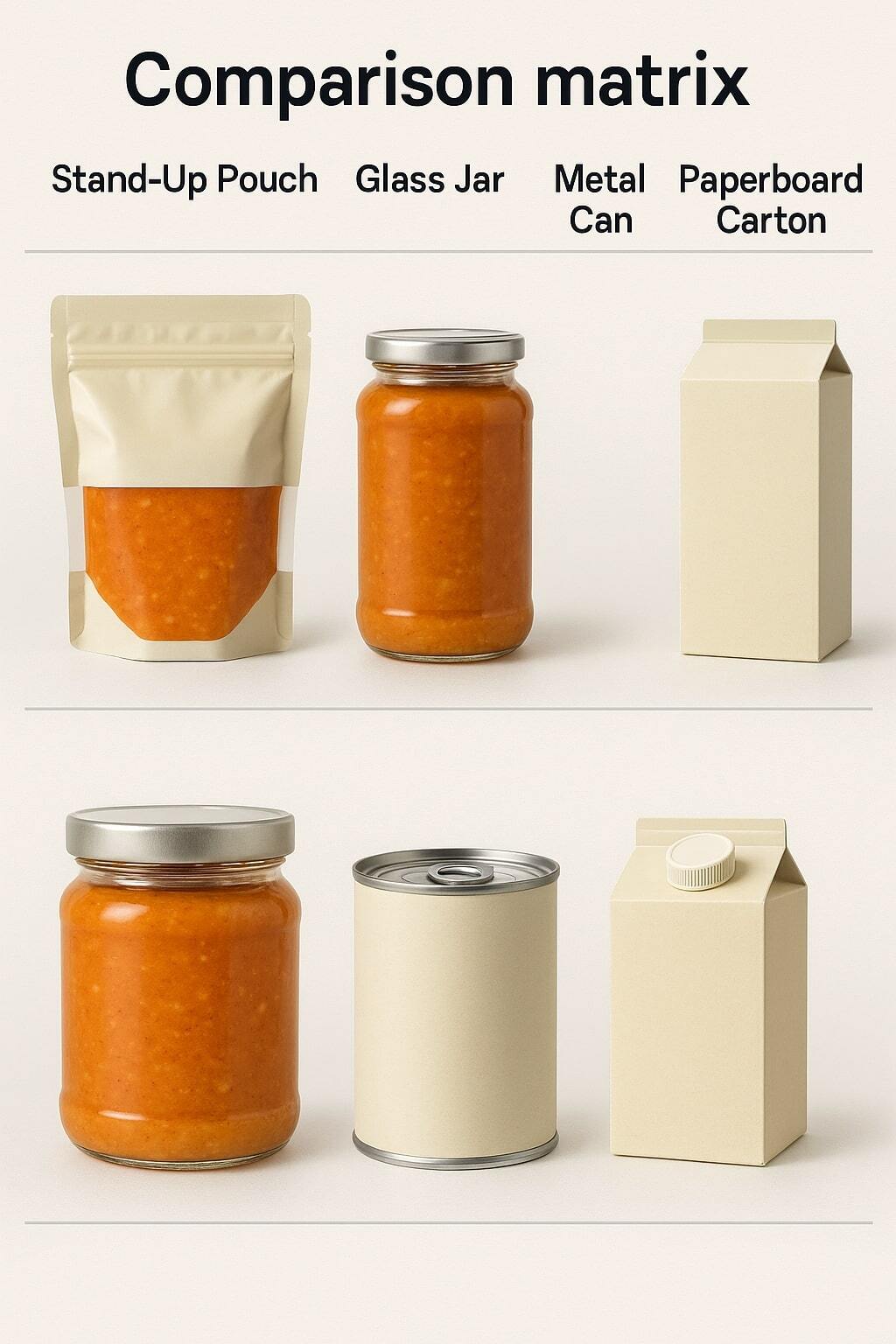

How pouches stack up against rigid plastics, glass jars, metal cans, and paperboard for food brands.

ESTIMATE MY PROJECT COST

Flexible packaging is growing rapidly in food, but traditional options remain relevant. This page compares cost, performance, sustainability, and perception—then links back to the complete food packaging guide for next steps.

Want a side-by-side for your exact food product?

ESTIMATE MY PROJECT COSTOr start with the broader food packaging guide.