Introduction

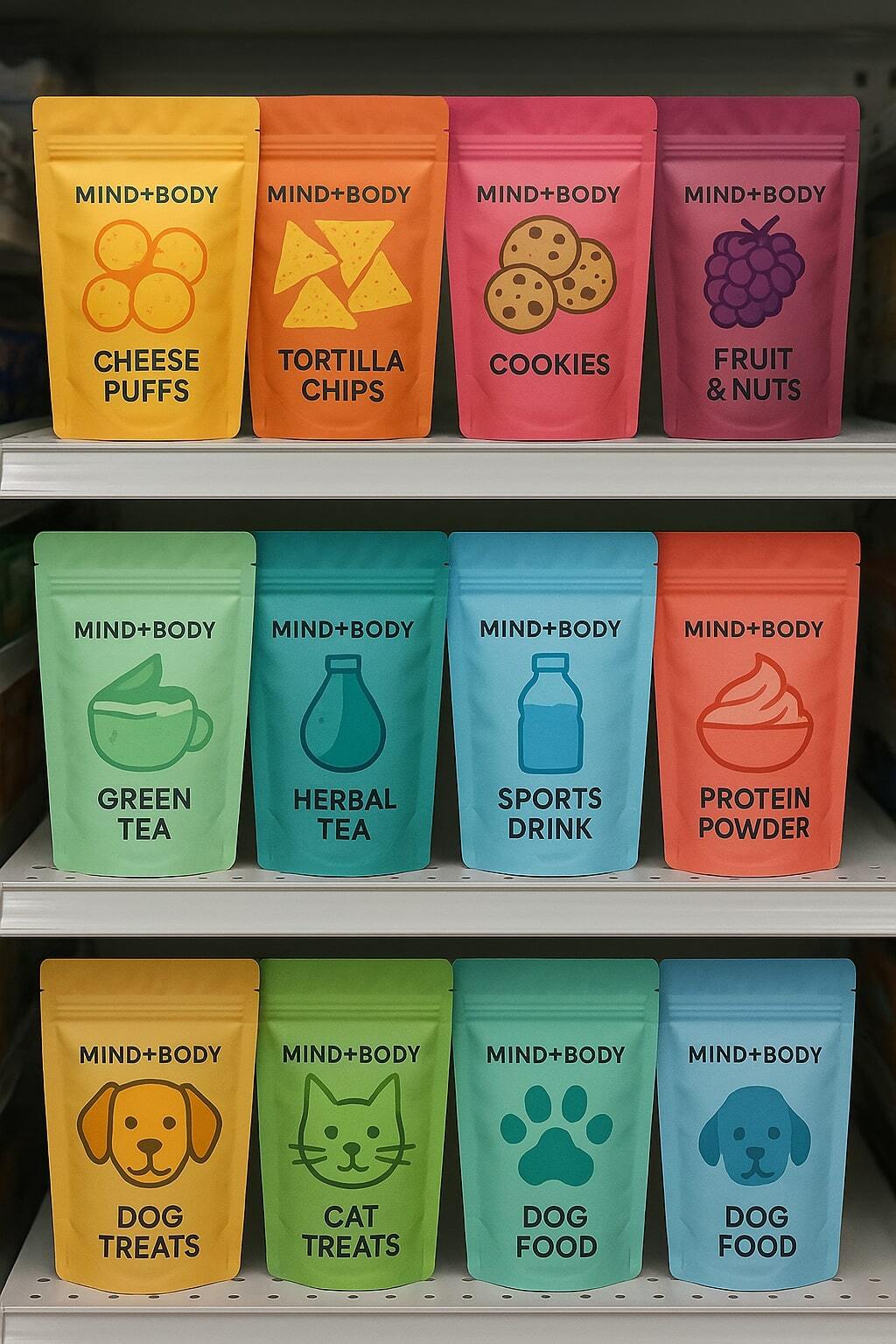

Flexible packaging has transformed how food brands bring products to market. From snacks to sauces, frozen meals to fresh produce, flexible packaging delivers a unique balance of protection, convenience, and shelf appeal. This guide covers real costs, benefits, risks, comparisons, and best practices for food companies evaluating flexible packaging products.