Introduction

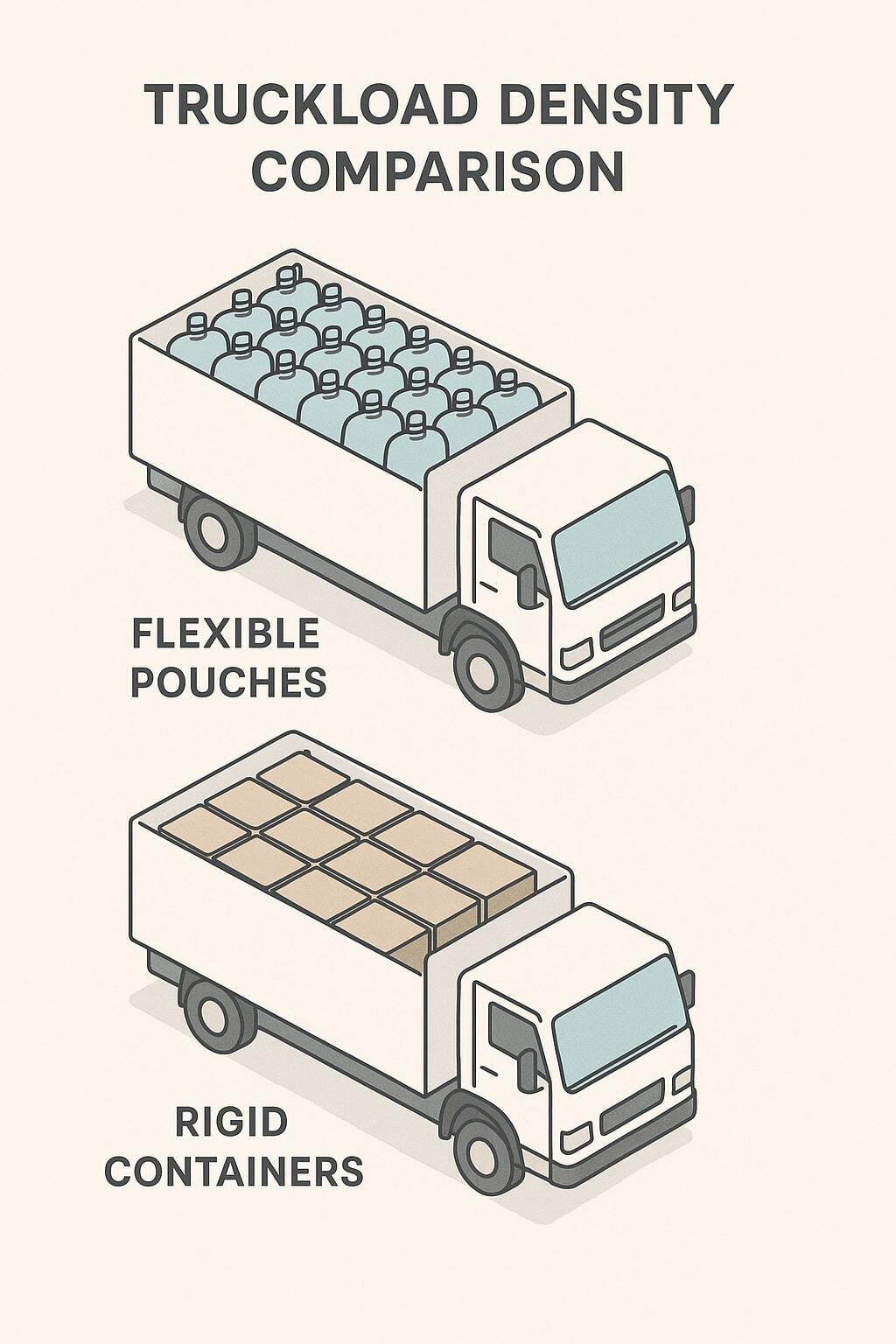

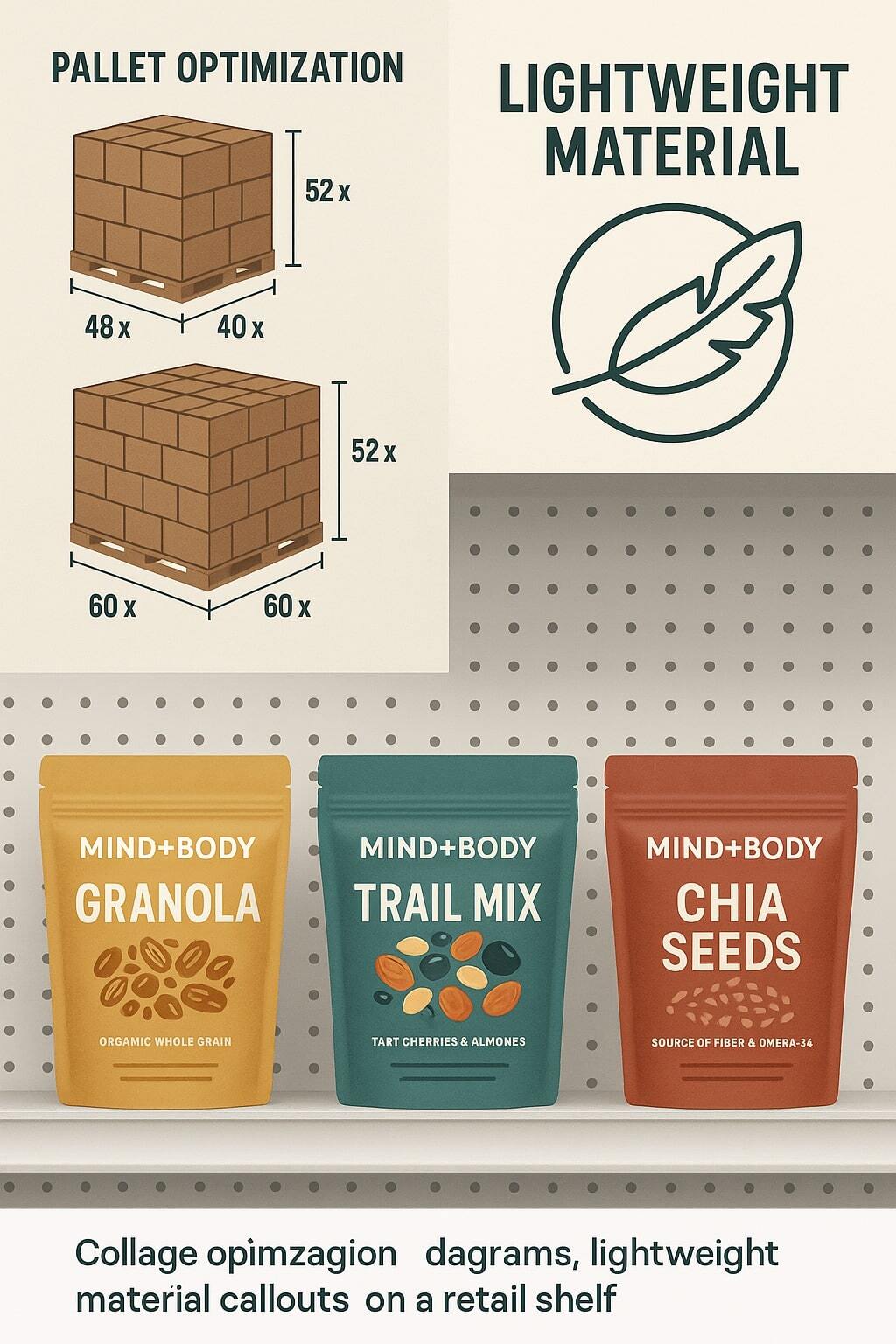

Many teams assume rigid packaging sets the baseline on price. In practice, flexible formats deliver better value by optimizing pallet density and protection. Dive deeper into value levers in the pillar page.

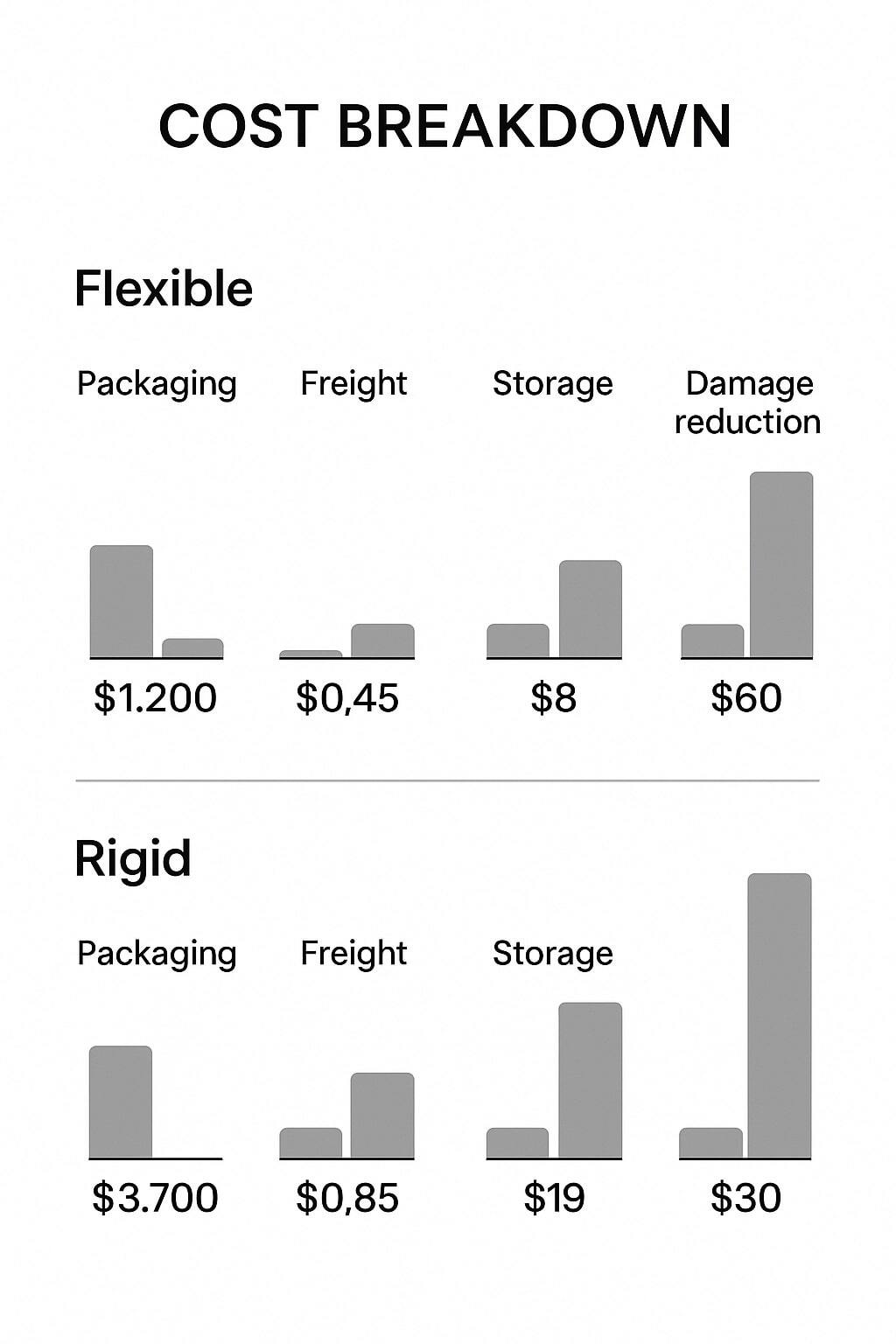

See how lightweight formats reduce freight and storage, and why total cost of ownership favors pouches. For a full systems view, read the Benefits of Flexible Packaging for Food Products pillar.

ESTIMATE MY PROJECT COSTMany teams assume rigid packaging sets the baseline on price. In practice, flexible formats deliver better value by optimizing pallet density and protection. Dive deeper into value levers in the pillar page.

Lightweight, compact packs unlock freight savings and lower warehouse fees. Even when unit cost is similar, total landed cost trends lower for pouches.

Using fewer materials and reducing product breakage creates savings often missed in per-unit comparisons. See the broad benefits summarized in the pillar overview.

For context beyond cost, review the benefits and risks in the main pillar page.

Rigid containers may look cheaper at the component level, yet flexible wins as freight, storage, and damage costs are accounted for.

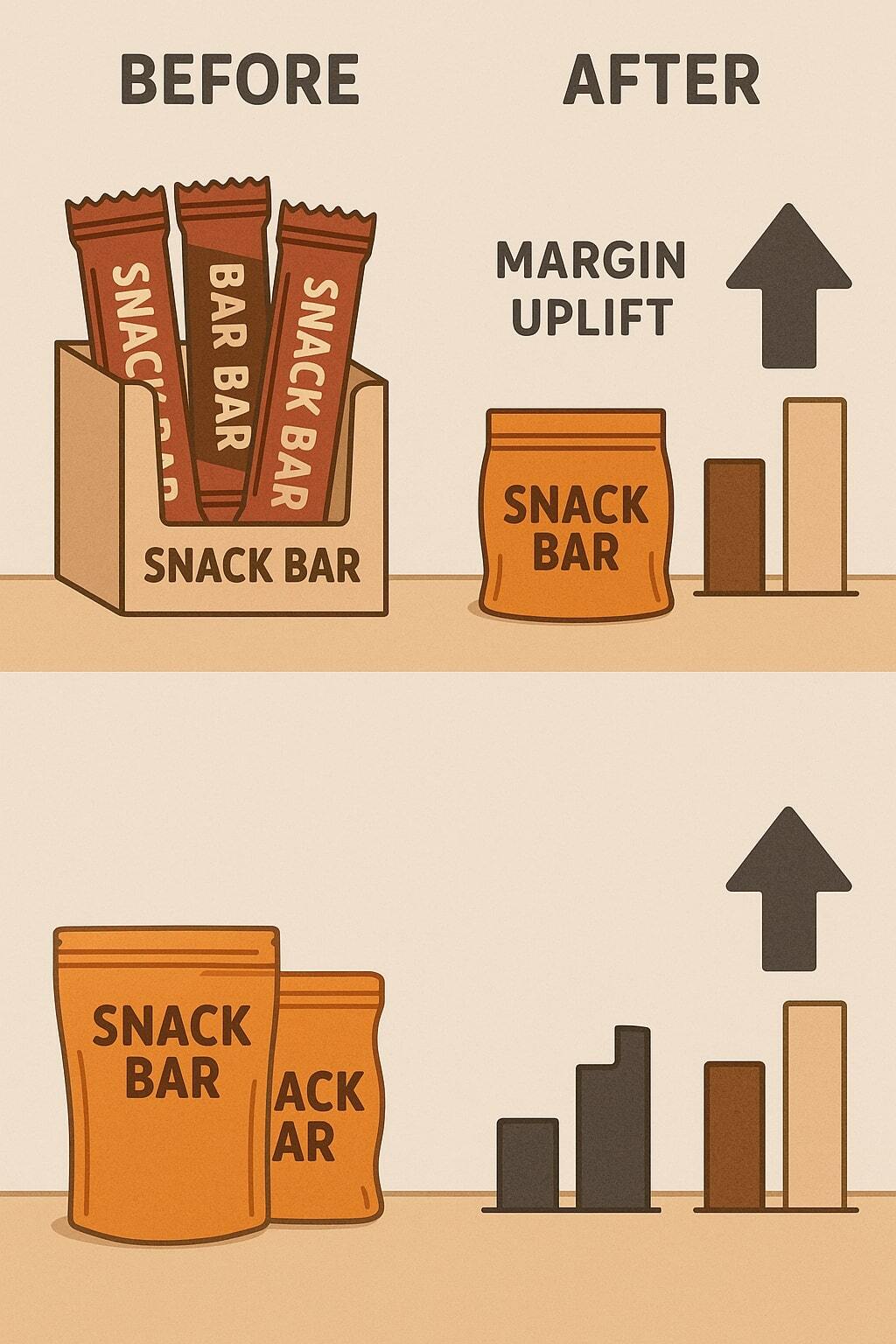

A mid-sized snack company increased per-unit packaging cost by 8% but reduced freight by 22% and storage by 30%, improving overall margins by 15% in one year.

Explore adjacent benefits on the pillar.

Compare total landed cost across your SKUs—start with the Benefits of Flexible Packaging pillar, then model pricing.

ESTIMATE MY PROJECT COST