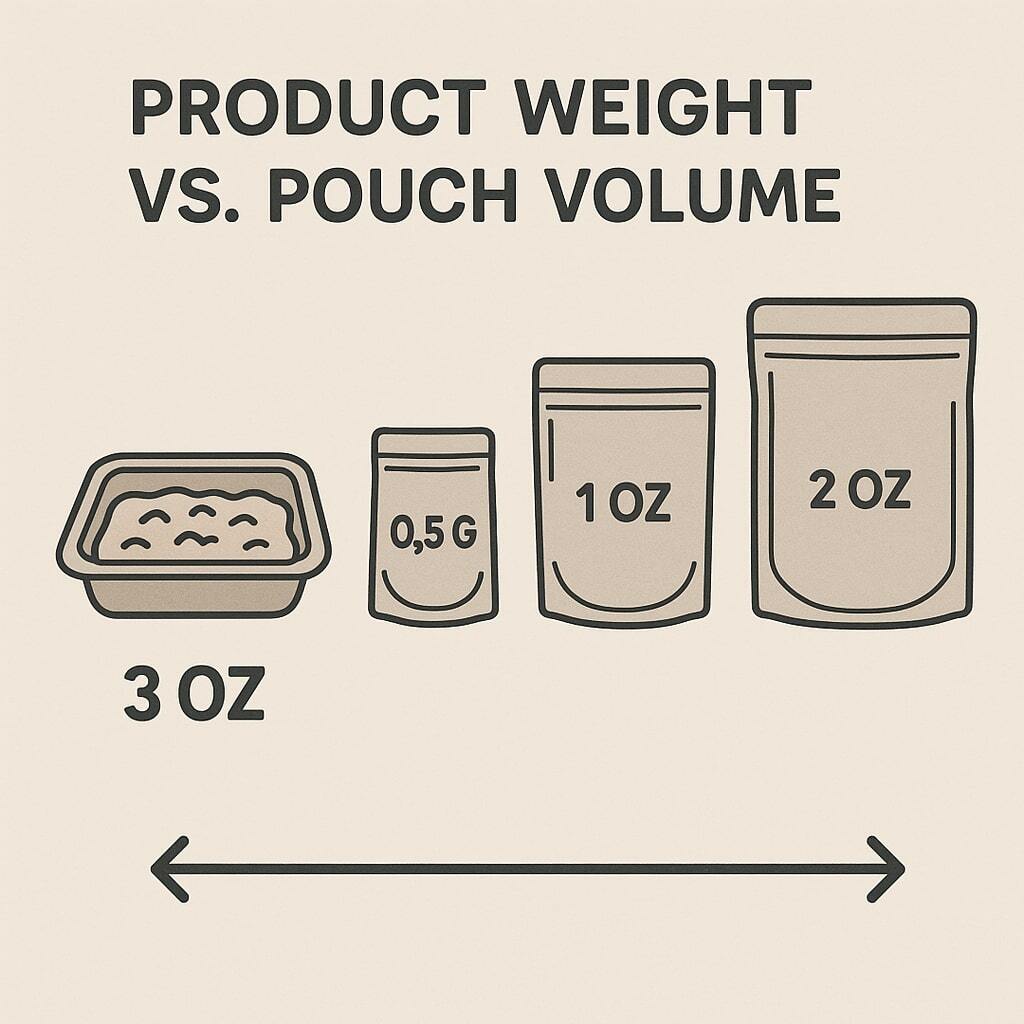

Mistake #1: Ordering the Wrong Size

“3 oz” refers to weight, not pouch capacity. Powders, liquids, and solids all need different volumes. Always test real samples with your product.

Avoid costly errors—wrong sizes, bad artwork, and material mismatches—by following our proven checklist and using the right tools.

ESTIMATE MY PROJECT COST

“3 oz” refers to weight, not pouch capacity. Powders, liquids, and solids all need different volumes. Always test real samples with your product.

Oily or wet products need high barrier films. Natural products need oxygen protection. Always match barrier level to product needs.

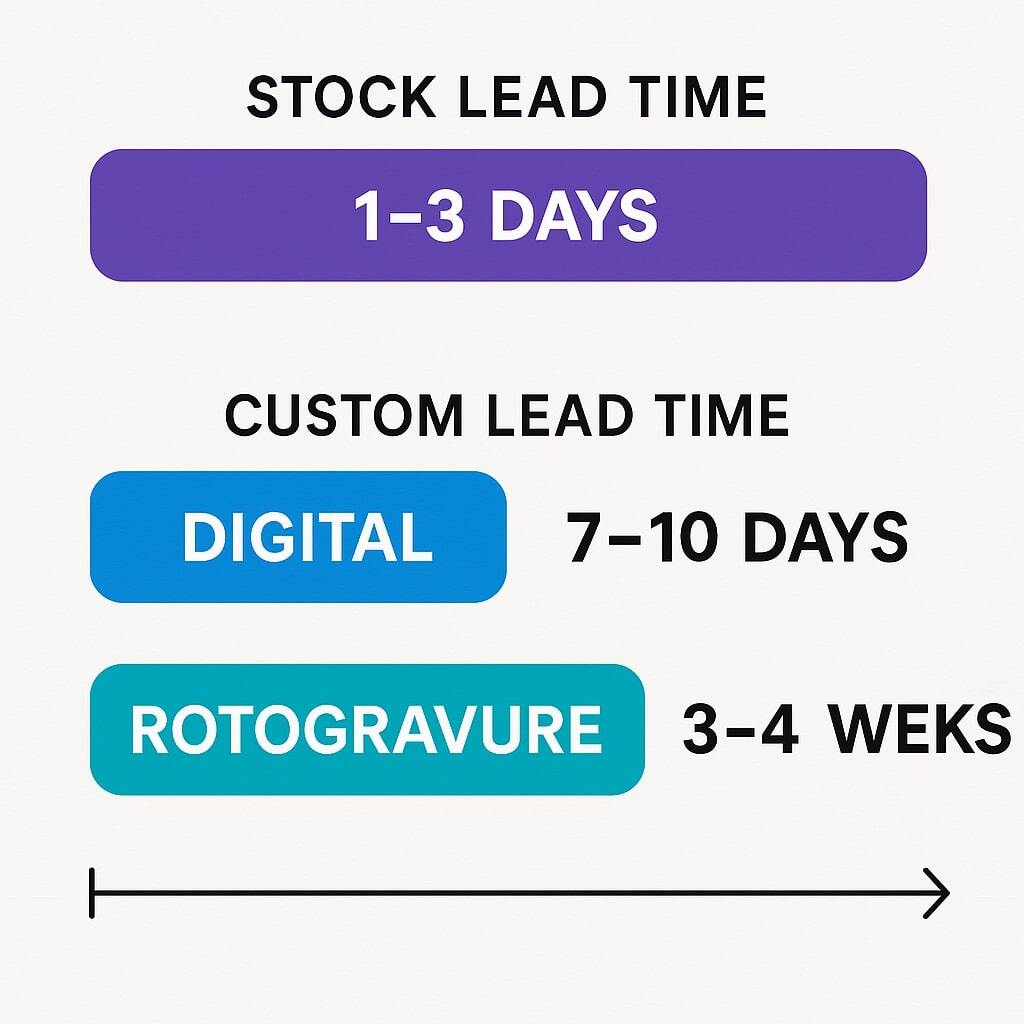

Digital printing is fast for small runs; rotogravure is cheaper at scale but slower. Use our calculator to align your quantity with the right print method.

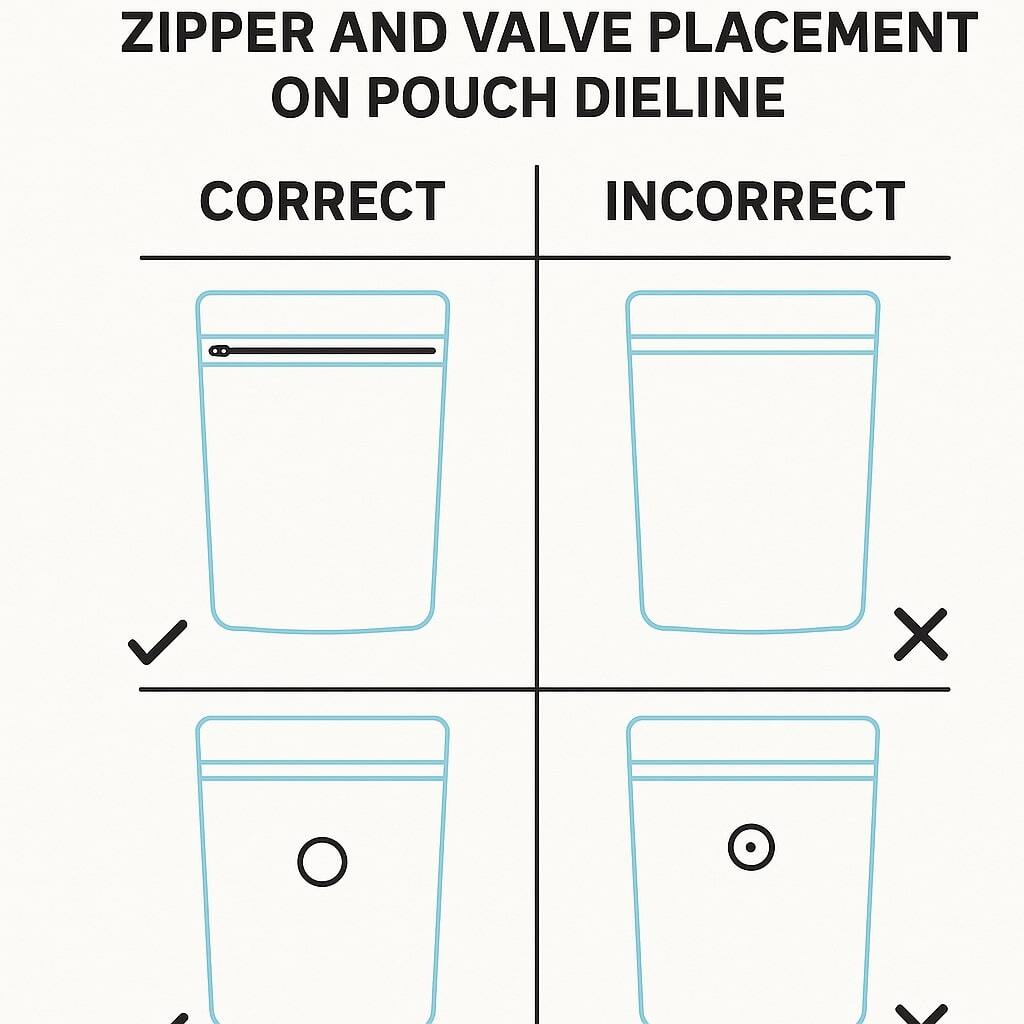

Incorrect placement can delay co-packers and spoil products. Confirm exact measurements and mark them on your dieline.

Always request digital and physical proofs for large runs. Have multiple stakeholders review to catch errors before production.