Introduction

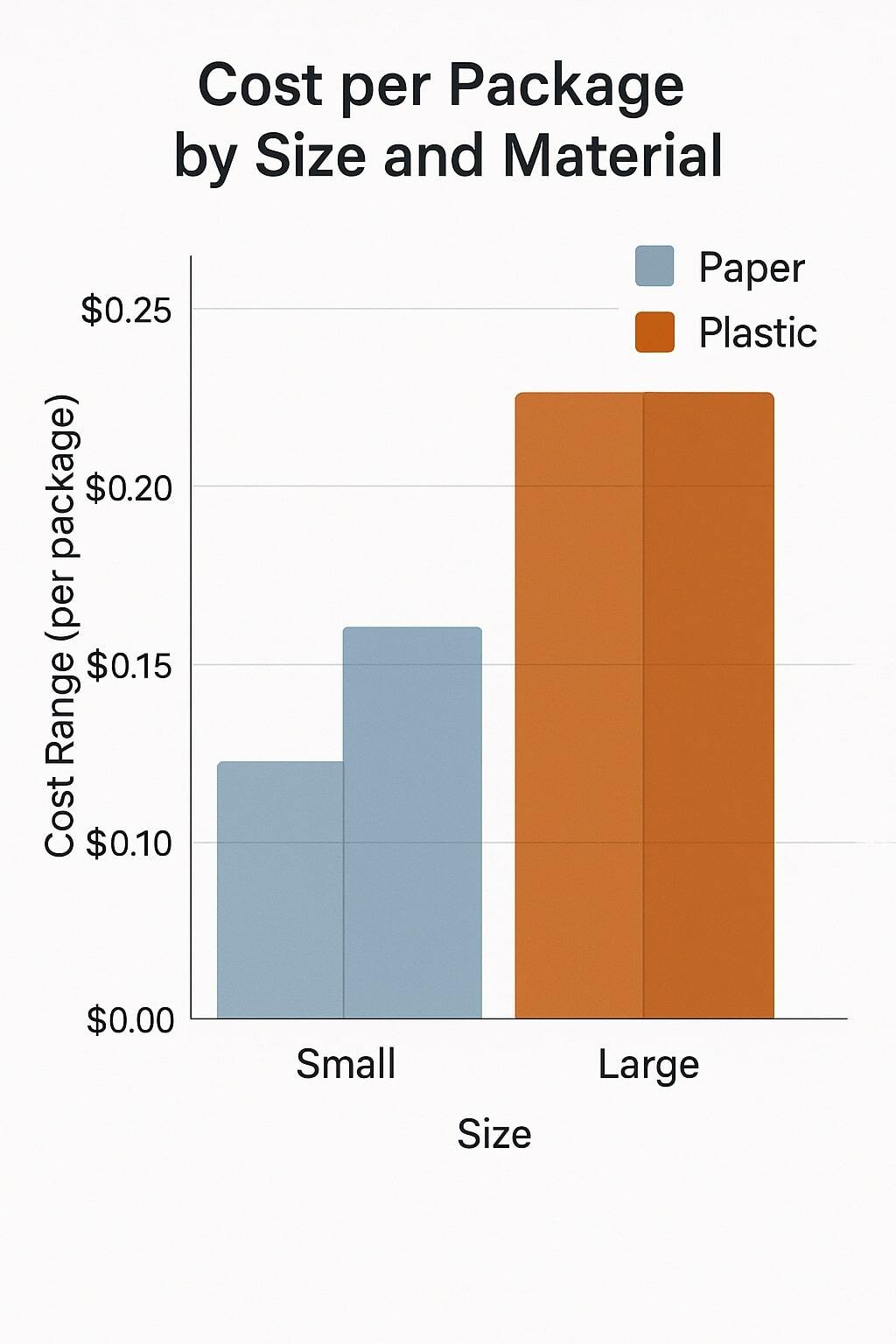

The cost of aseptic beverage packaging depends on multiple factors—material type, package volume, filling technology, and production scale. While the initial investment can appear higher than traditional packaging methods, aseptic systems often deliver significant long-term savings through reduced spoilage, lower transportation costs, and extended shelf life. Learn the full breakdown below, or explore the complete guide to aseptic packaging.