Introduction

Traditional packaging often relies on refrigeration and preservatives. Aseptic systems sterilize and seal in a controlled environment, enabling ambient shelf life and global distribution.

Compare shelf life, logistics, safety, and sustainability—then see how the process works in the aseptic step-by-step pillar.

ESTIMATE MY PROJECT COSTTraditional packaging often relies on refrigeration and preservatives. Aseptic systems sterilize and seal in a controlled environment, enabling ambient shelf life and global distribution.

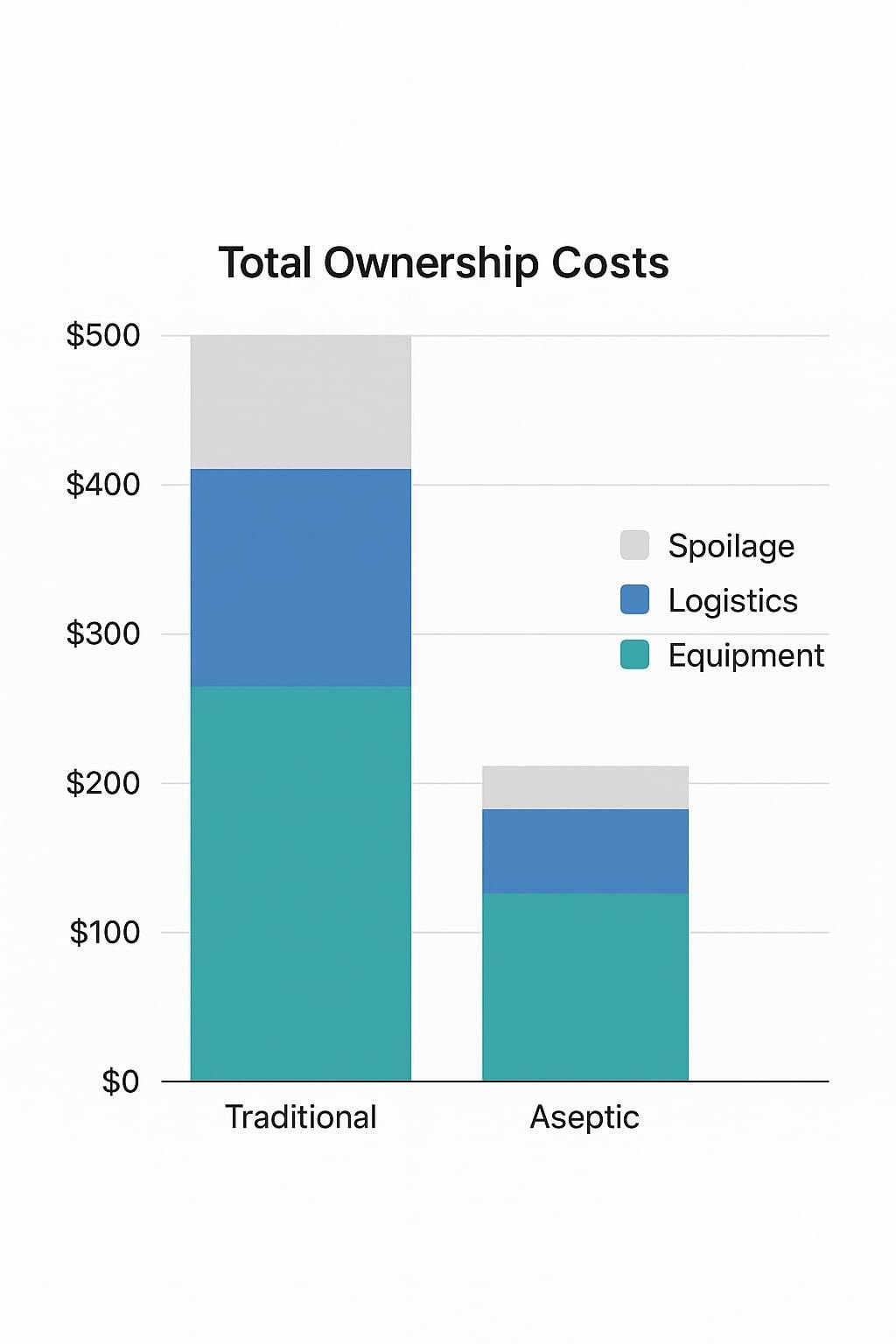

Traditional: lower equipment but ongoing refrigeration and higher spoilage. Aseptic: higher upfronts with long-term savings in logistics and waste—especially at scale.

Traditional: spoilage risk and cold-chain dependence. Aseptic: complex sterilization and skilled operators. The right choice depends on growth goals and product stability.

Beverage Brand: Shifted from refrigerated bottles to aseptic cartons, extending shelf life to 10 months, cutting logistics by 30%, reducing contamination by 70%, and enabling international growth.

For the underlying steps, see the pillar.

Compare scenarios for your SKU—review the Aseptic Step-by-Step Guide and get a fast estimate.

ESTIMATE MY PROJECT COST