1. Do You Offer Both Stock and Custom Pouches?

Ensure your supplier can meet both urgent stock needs and full custom print runs as your business evolves.

Avoid surprises—ask these 10 critical questions to ensure quality, lead times, sustainability, and support from your pouch partner.

ESTIMATE MY PROJECT COST

Ensure your supplier can meet both urgent stock needs and full custom print runs as your business evolves.

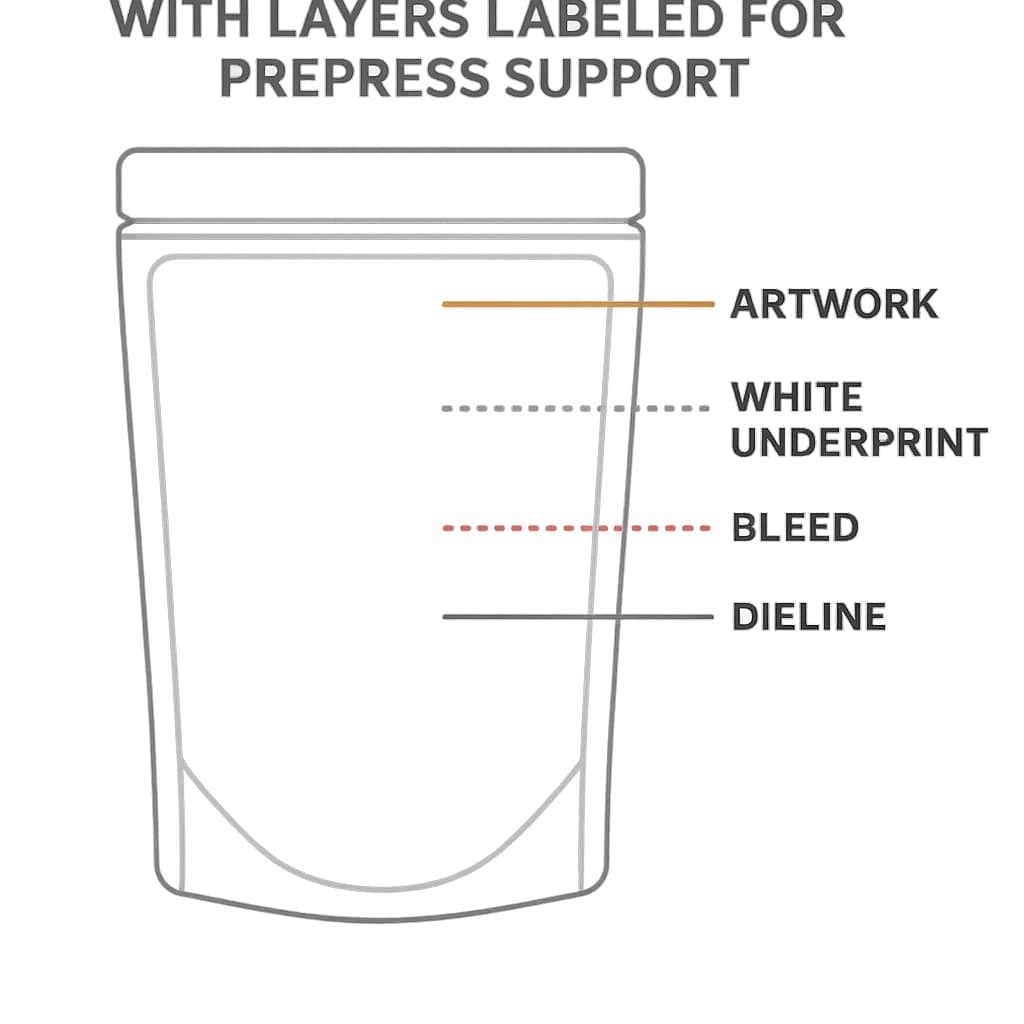

Look for template support, layering guidance, and preflight checks to catch errors before printing.

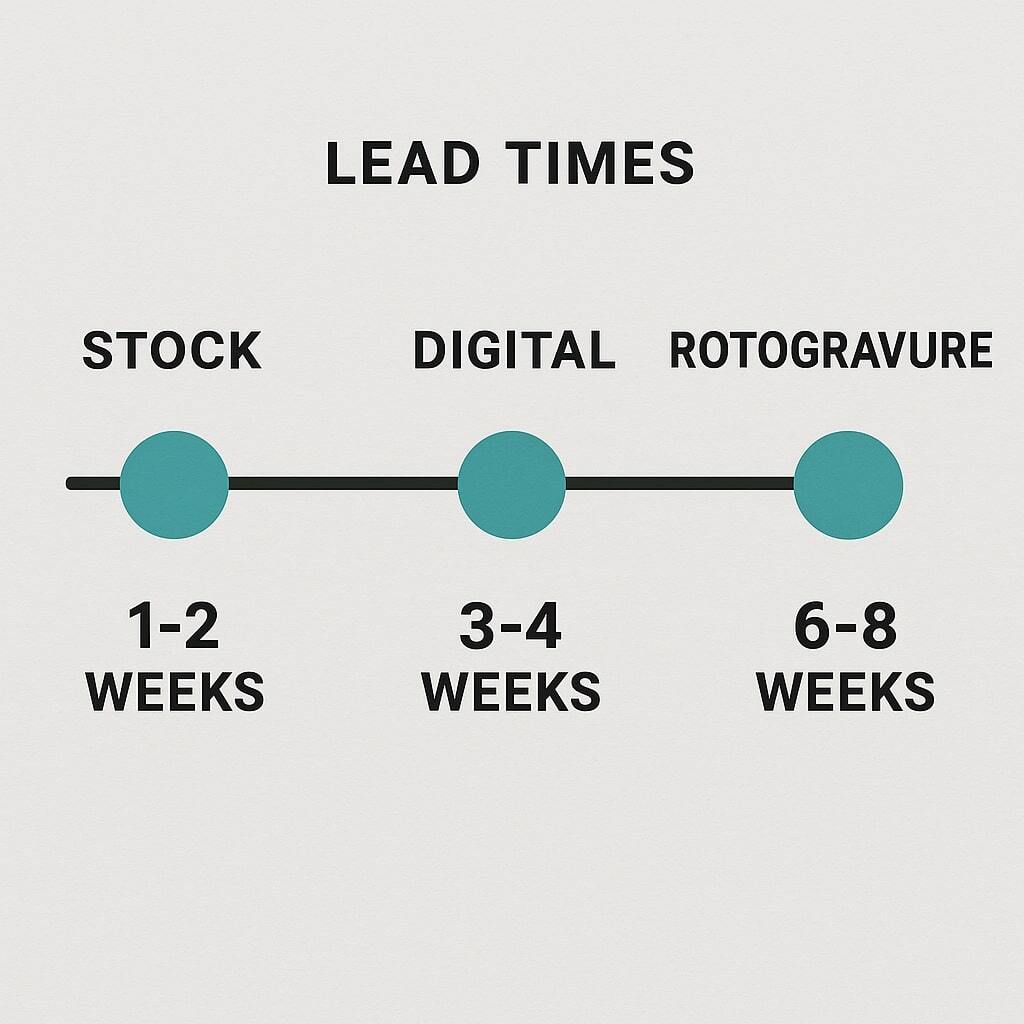

Ask about MOQs for digital (1,000+) and rotogravure (25,000+) to plan your budget and timeline.

Match your volume and quality needs with the right method: digital for flexibility, roto for scale.

Verify availability of recyclable mono-material, compostable films, and recyclable-ready laminates for future compliance.

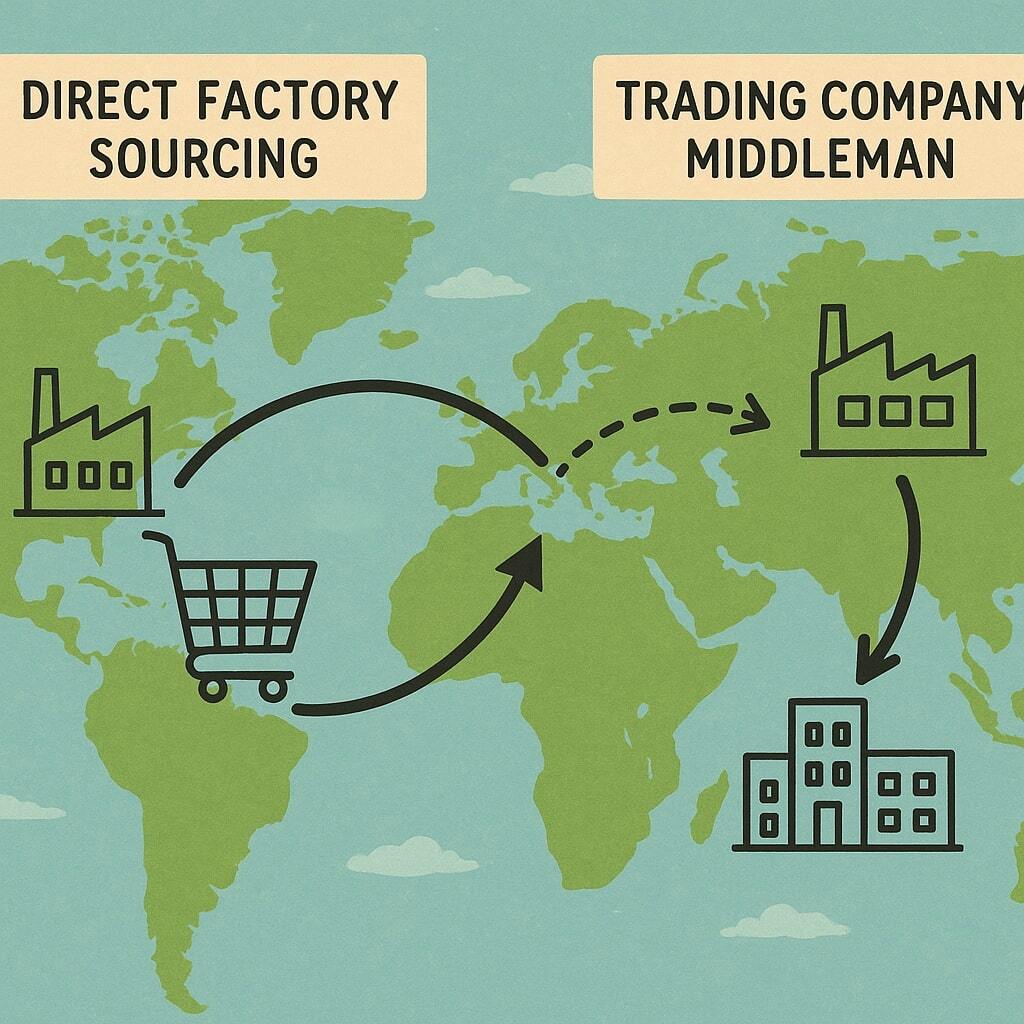

Prefer suppliers with direct factory relationships and on-the-ground QC to avoid delays and miscommunication.

Check for training, white-label samples, quoting tools, and dedicated rep support to help you sell pouches confidently.

Ask about their defect policy, proof processes, and quality guarantees to protect your business and reputation.

Ensure you have direct access to project managers or reps who respond promptly—no buried contact forms.