When it comes to food packaging, quality is one of the characteristics that matters most to your customers. The quality of your company’s food packaging can impact the freshness of your product, as well as presentation and durability. Whether your customers are conscious of it or not, quality food product packaging speaks volumes about your company and your product.

For example, think about the time you were searching for canned soup at the grocery store. When you come across a dented can, what is your typical reaction? Do you ignore the can and move forward with your purchase? Or do you put the can back and select another product that isn’t damaged?

This is a situation that occurs at grocery stores across the country. Damaged food packaging can result in loss of sales. You get that product presentation matters to your customer, and quality is surely part of your overall presentation. We might not be analyzing food cans in this post, but the point is that quality matters to customers, whether it’s from a can or a flexible package.

You wouldn’t settle for a poor quality product. Don’t skimp on the quality of your packaging.

Ensuring The Best Quality Flexible Retail Packaging

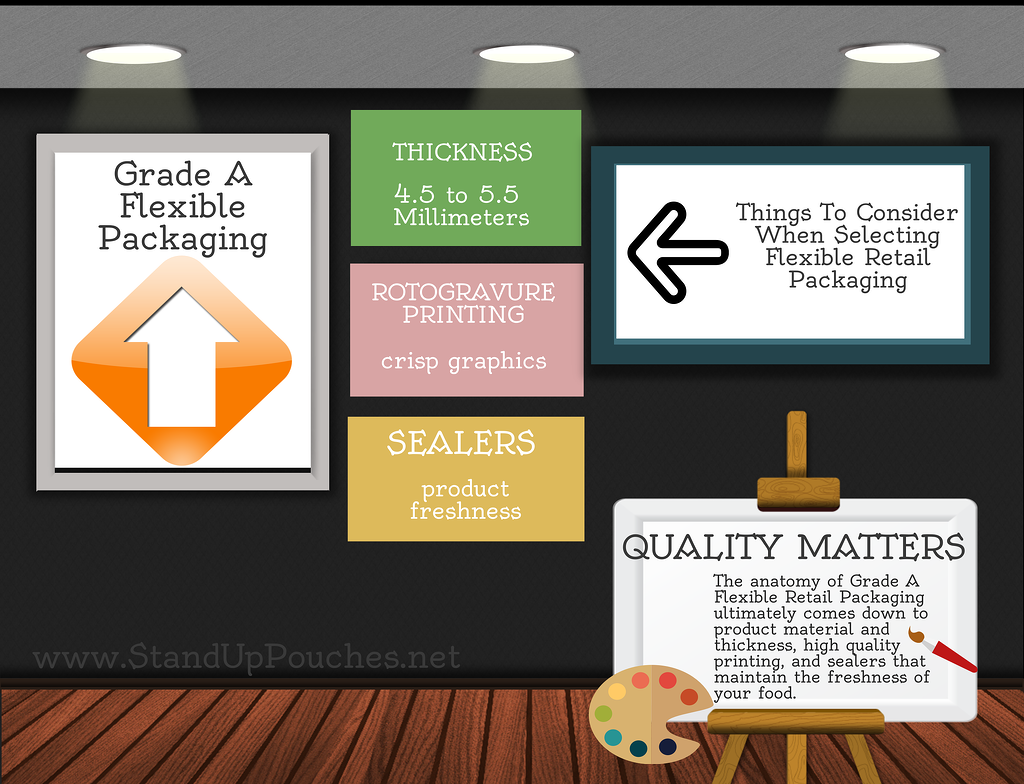

When you are shopping for flexible retail packaging, there are several product characteristics to consider before moving forward with your purchase. Whether your product is cereal or spices, paying attention to the quality of your custom retail packaging can save you headache (and money) in the long run.

Here are the top quality factors to consider when selecting flexible retail packaging.

- Grade A Flexible Retail Packaging Product Thickness: 4.5 to 5.5 Millimeters.

When you are selecting quality flexible retail packaging, one of the first characteristics to consider is thickness. This might seem like a minor detail, but neglecting the thickness of your packaging can pose all kinds of problems for both your product and presentation.

Using another real world example of product quality (and thickness issue), think back to a time when you were carrying your groceries into your house using those run-of-the-mill plastic grocery bags. You know that the weight of the bags is pushing the limits, but you are only steps away from the door and you’re home free— or not.

Suddenly, your grocery bags give out and product falls out all over the ground. Milk jugs bust open and you lose half a gallon. Your glass jar breaks that was containing your favorite jelly. Now you’re left with a big mess, you lost money, and you are angry that the grocery store couldn’t invest in a better quality bag; and it was all because they wanted to save a couple cents.

So, how do you avoid frustrating your customers over the thickness of your flexible retail packaging? Aim to keep your packaging at a target thickness of 4.5 to 5.5 millimeters. Thinner flexible retail packaging probably won’t break like grocery bags, but thicker packaging ensures that the bag will stand up on the shelf on not lose shape.

We take flexible retail packaging thickness seriously here at Stand Up Pouches. In fact, each bag undergoes a thickness test for quality purposes. You can learn more about the process by watching our video that shows how it’s done.

Thicker packaging might add a few extra dollars to your invoice, but pleasing your customer is always worth the cost.

- Grade A Flexible Retail Packaging Presentation: Rotogravure Printing

Your food packaging only has several seconds to impress customers enough to consider your brand. With fierce competition in the food marketing world, you can’t afford to skimp on graphics. Low quality graphics and printing might just cost you a sale.

Rotogravure printing for flexible retail packaging yields different results than flexographic printing. Rotogravure printing will give your flexible retail packaging bold, intense, and beautiful graphics that are shelf ready and eye catching to customers. When you use rotogravure printing, the value and perception of your flexible retail package instantly increases.

You can’t beat the crisp graphics with rotogravure printing. When you are designing Grade A flexible retail packaging, there’s simply no better option in terms of print.

- Grade A Flexible Retail Packaging Sealers: Ensuring Product Freshness

One of the biggest advantages of flexible retail packaging is maintaining your food product’s freshness factor for extended periods of time. Your package’s sealer is responsible for keeping your product fresh. Not all sealers are created equal, so carefully consider your sealer options by using these guidelines.

There are several sealer options in the flexible packaging industry. First, heat sealers are standard for Stand Up Pouches, and this method can be applied to packages that are 8mm minimum. This method is sufficient for most orders.

Lower quantity orders of flexible retail packaging can benefit from hand sealers. The disadvantage to this method is that it’s nearly impossible to apply to large orders. However, this method is perfect if your order number is low and you are looking for a quality sealer method.

While the single impulse heater is the most common in the industry, double impulse heaters produce better results. It’s pricier than the single impulse heater option, but it ensures top-quality freshness for your food products.

The general price point for sealers boils down to effectiveness. Price points for sealers rise as they become more effective and their quality increases. You will shell out a bit more money for options such as double impulse heaters or the mini conveyer belt option, but you will instantly see Grade A quality in your packaging.

Grade A Flexible Retail Packaging Recap

The anatomy of Grade A Flexible Retail Packaging ultimately comes down to product material and thickness, high quality printing, and sealers that maintain the freshness of your food. When you look through the eyes of your customers, it’s easy to see why quality matters. Customers are looking for quality packaging that looks nice and has a great presentation factor at the store.

Meeting these criteria will enhance the quality of your product and keep your customers coming back for more.